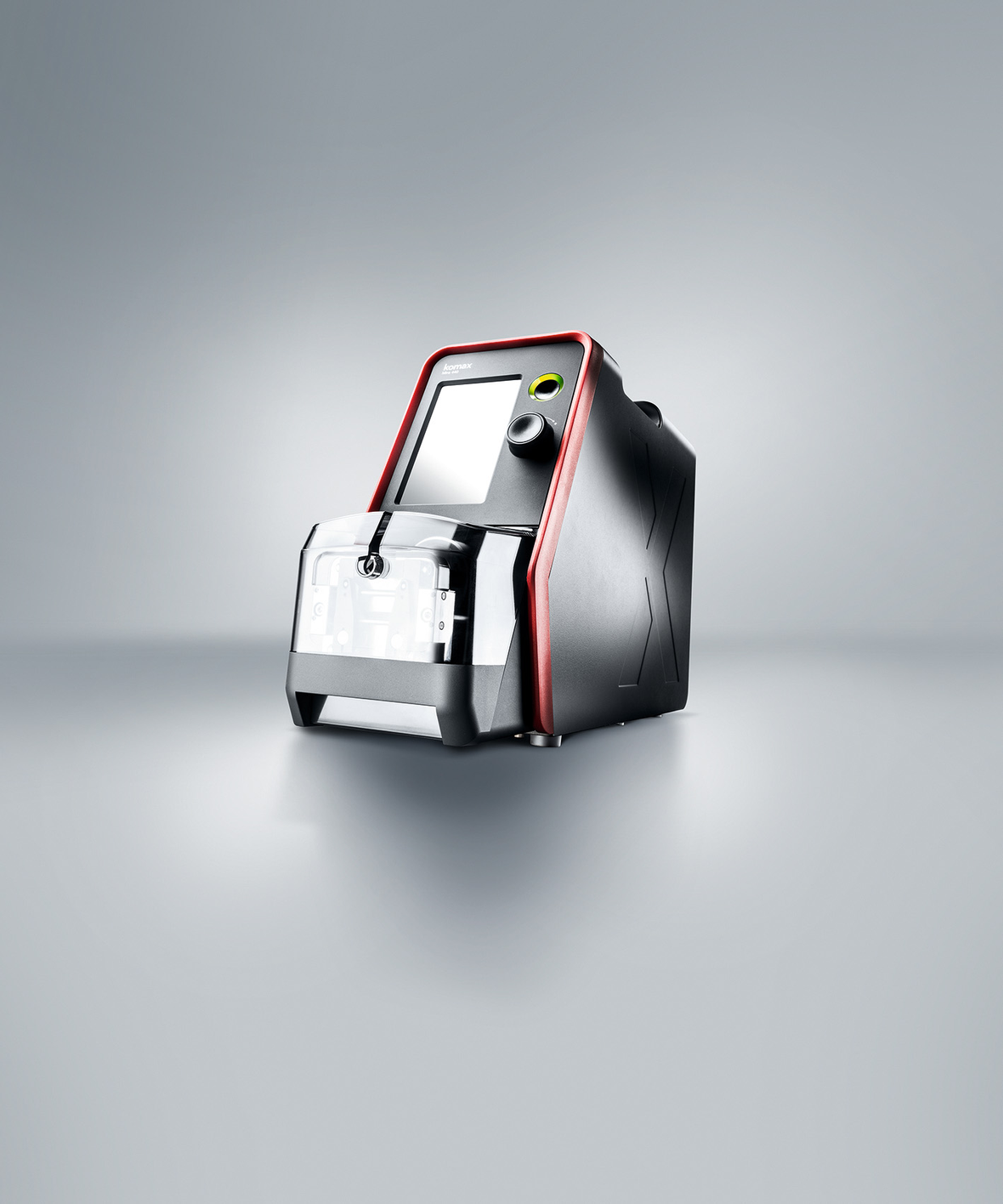

Wire Stripper

Mira 440

The Miras 440 stripping machine is particularly suitable for processing multi-layer cables such as coaxial and triaxial cables as well as single-core and multi-core wires.

Hand rest for better working

The Mira 440 ensures posture-friendly work thanks to the ergonomic hand rest and low-lying wire line.

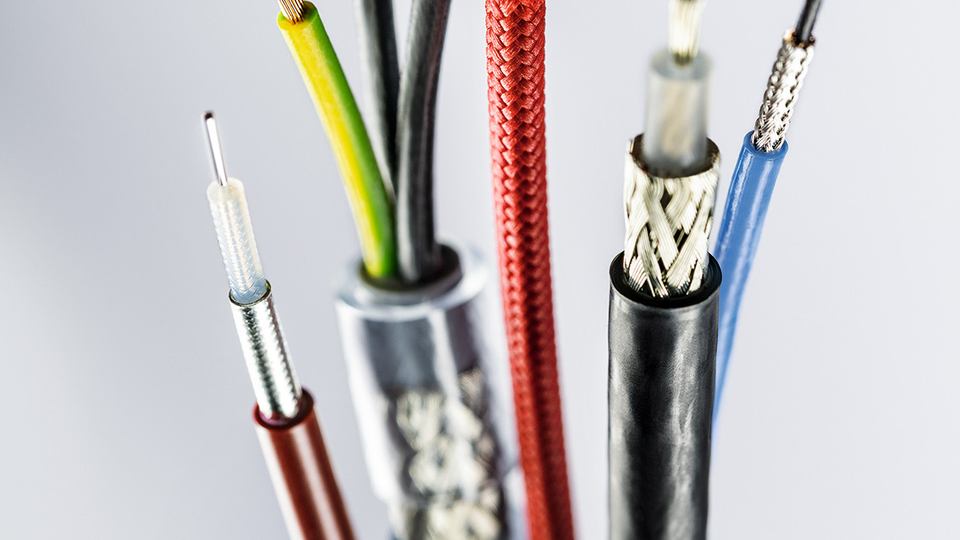

Different processing types for many wire types

The Mira 440 enables assemblies of various wire types such as shielded multi-core cables, single wires with textile braiding, and coaxial cables.

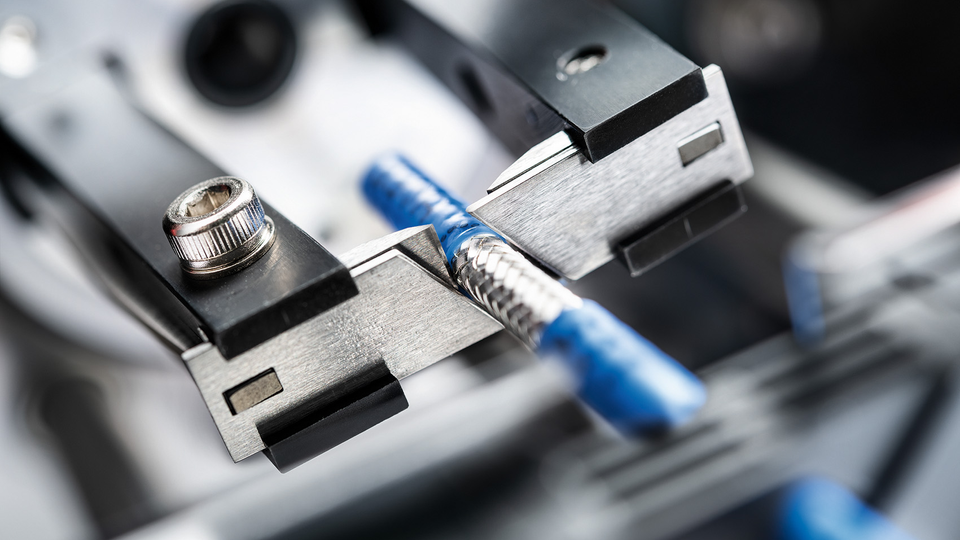

Precise stripping of difficult wire types

Thanks to its sophisticated cutting technique, the Mira 440 lends itself to high-quality and smooth processing of coaxial, triaxial and hybrid cables.

| Specification name | Specification value |

|---|---|

| Conductor cross section (stripping) of single-conductor wire min. | 0.02 mm² |

| Conductor cross section (stripping) of single-conductor wire max. | 13 mm² |

| Wire outer diameter max. | 9 mm |

| Strip lengths, full stripping max. | 40 mm |

| Number of entries in the article library | 1000 |

| Number of entries in sequence library | 1000 |