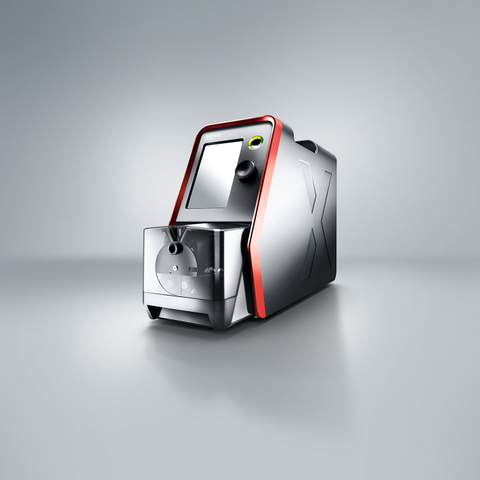

Mira 340

The programmable Mira 340 stripping machine enables automated processing of wires with an outer diameter of up to 8 mm and a strip length of 72 mm.

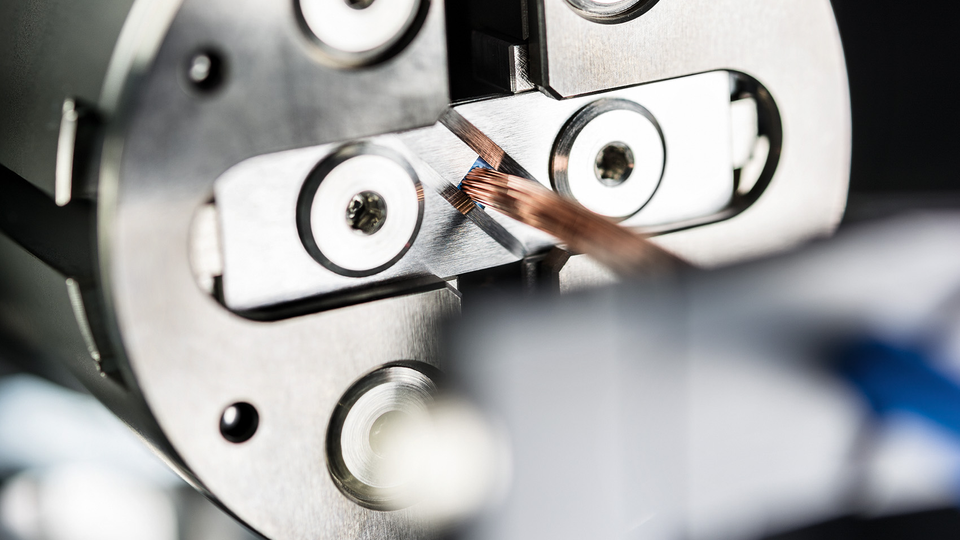

Precise stripping with a rotation cut

The rotation cut with 4X blades strips with greater precision and provides a smoother cutting surface than V blades.

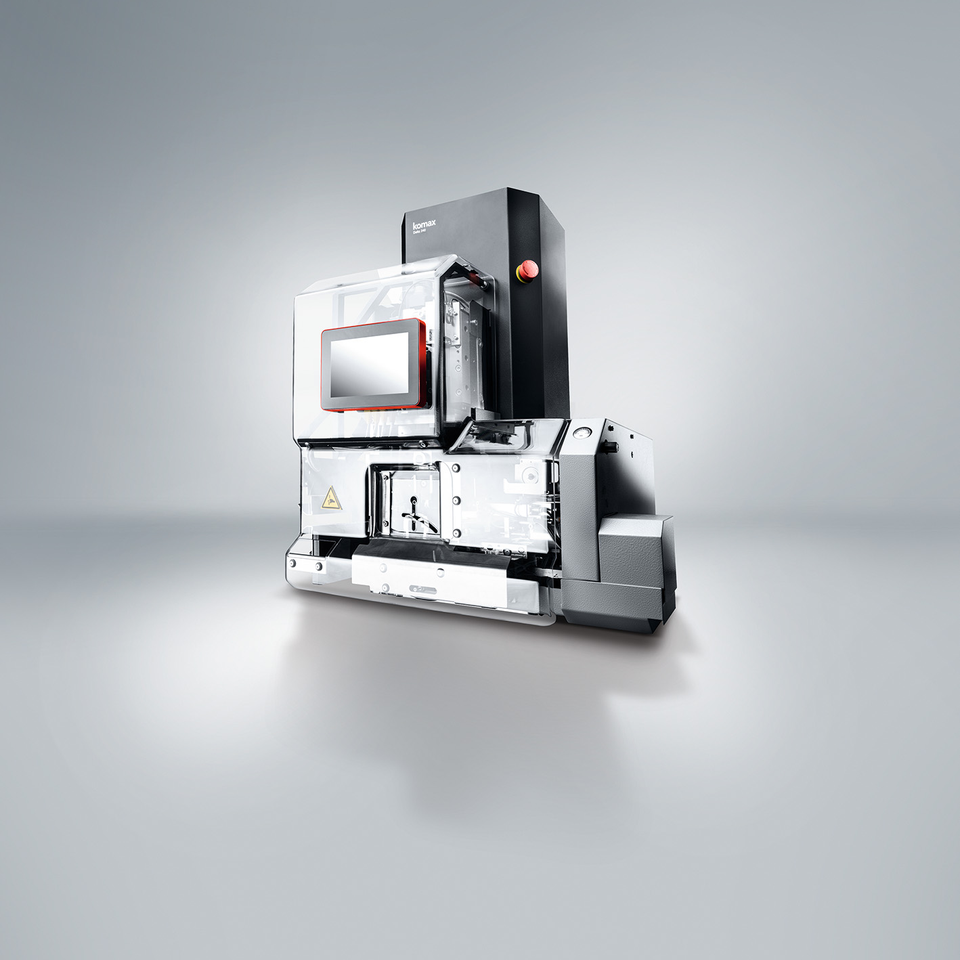

Mira 340 Q with ACD incision monitoring

ACD detects and signals the slightest contact between the blade and conductor and serves as an important monitoring function, especially for difficult lines.

Easy article selection with barcode scanner

Selecting articles with barcode scanning not only saves time but also prevents errors that can occur during manual input.

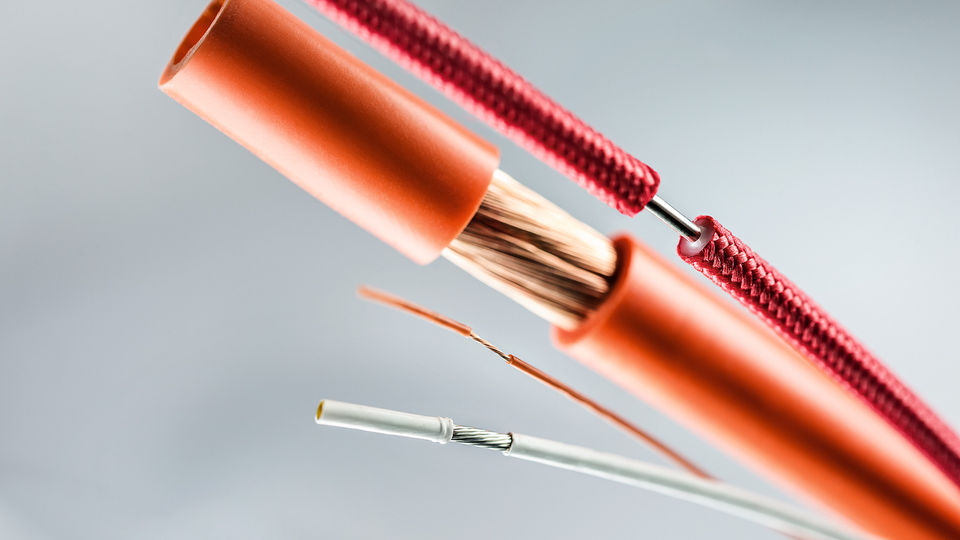

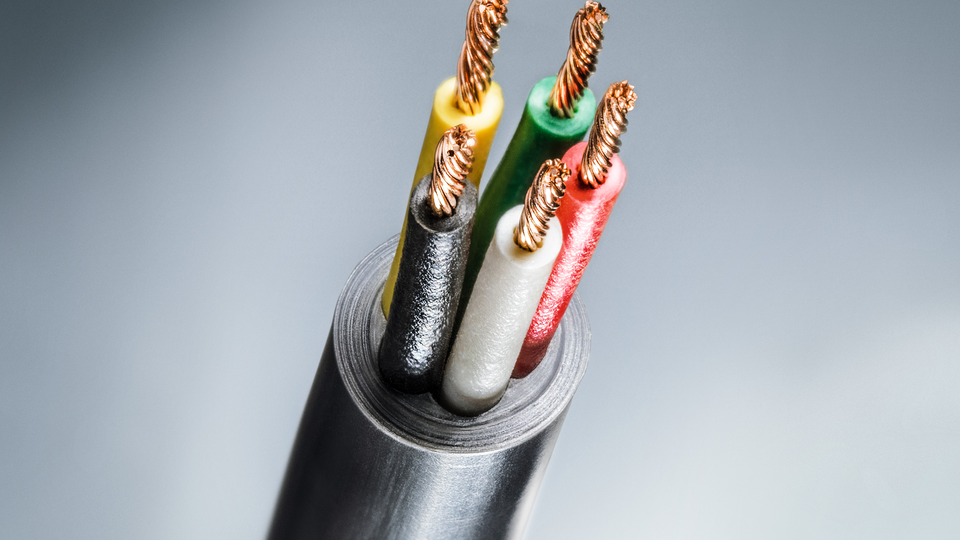

Processing of a wide variety of wire types

The Mira 340 processes a wide range of wire types and sophisticated insulation, like tough Teflon®, flexible silicone, and fiber braiding.

Sharp stripping of wires and cables

The Mira 340 can also be used for multi-stage stripping with full and partial stripping, offset stripping, short cuts on multi-core or multi-layer wires.

| Specification name | Specification value |

|---|---|

| Wire outer diameter max. | 8 mm |

| Strip lengths, full stripping max. | 72 mm |

| Increment of strip length | 0.01 mm |

| Insertion depth with standard grippers min. | 12 mm |

| Number of entries in the article library | 3000 |

| Number of entries in sequence library | 1000 |