Crimp to Crimp

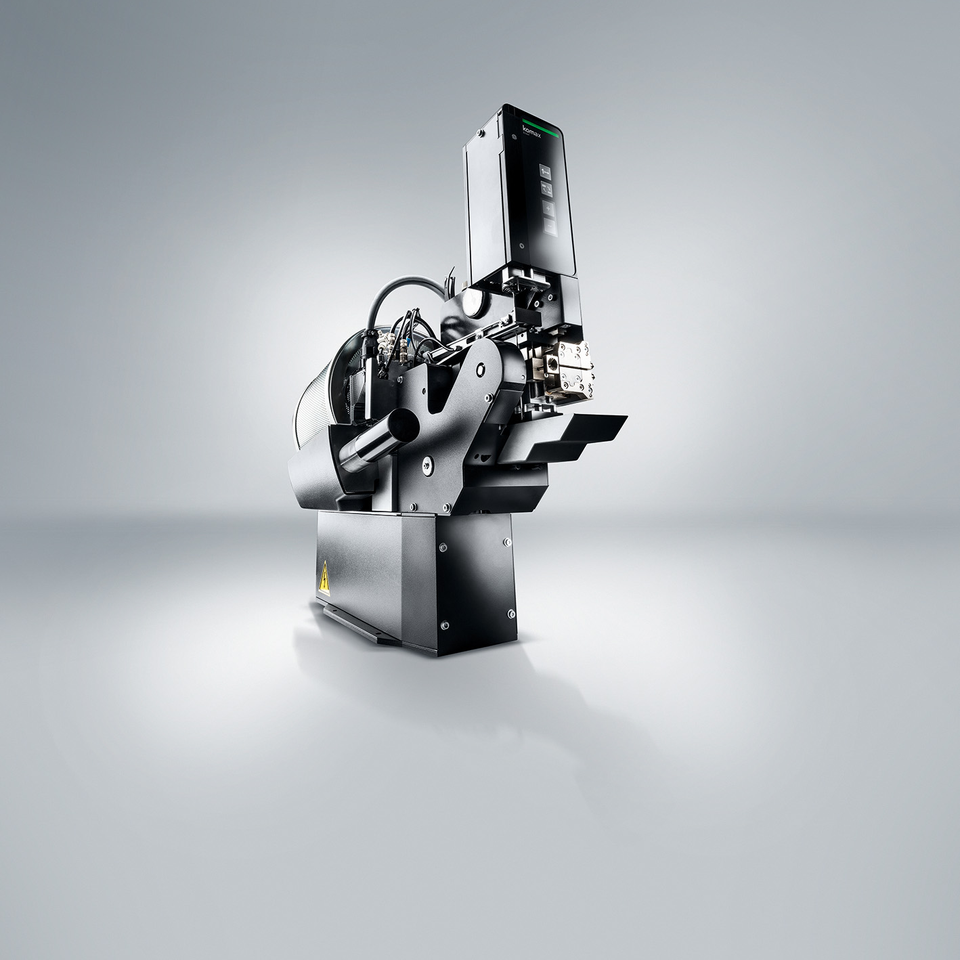

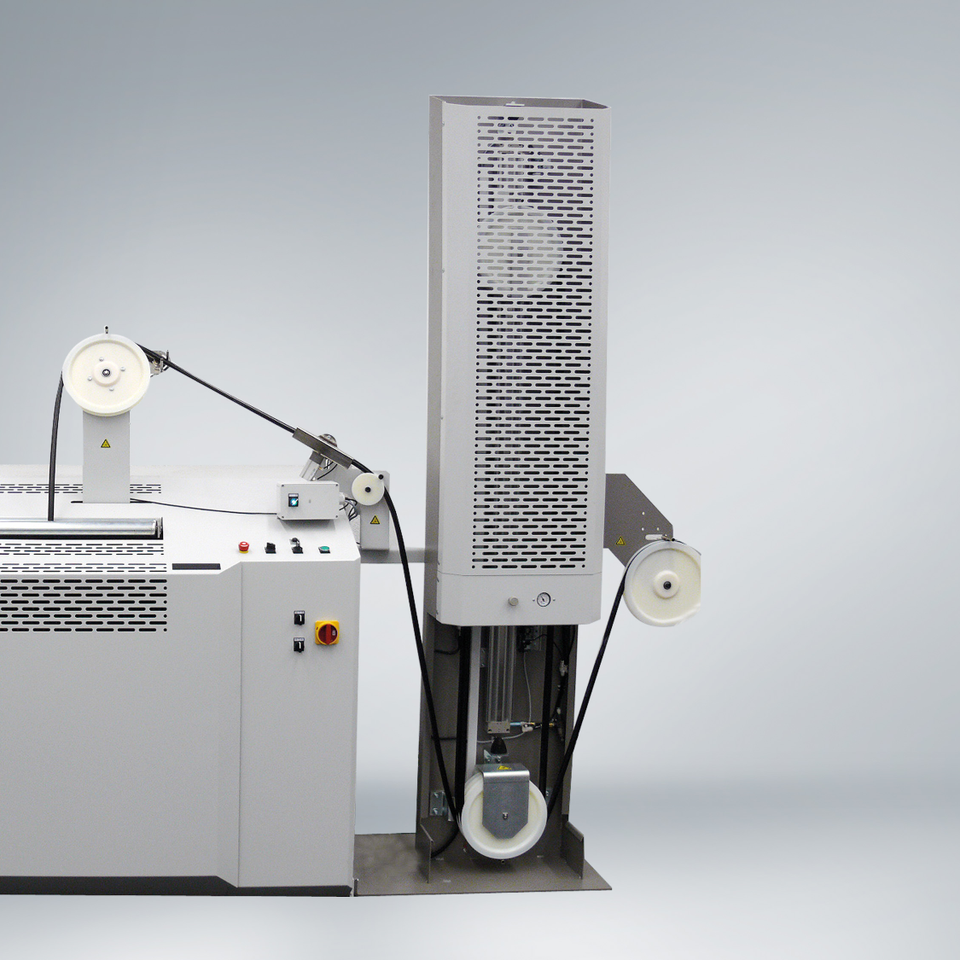

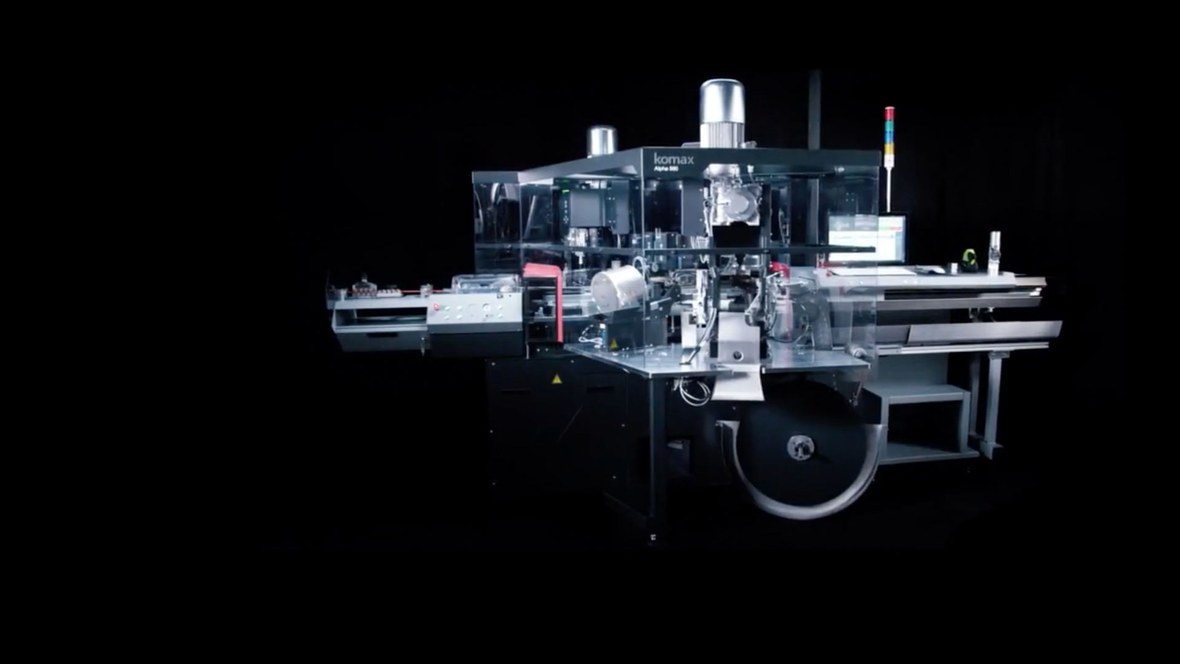

Alpha 560

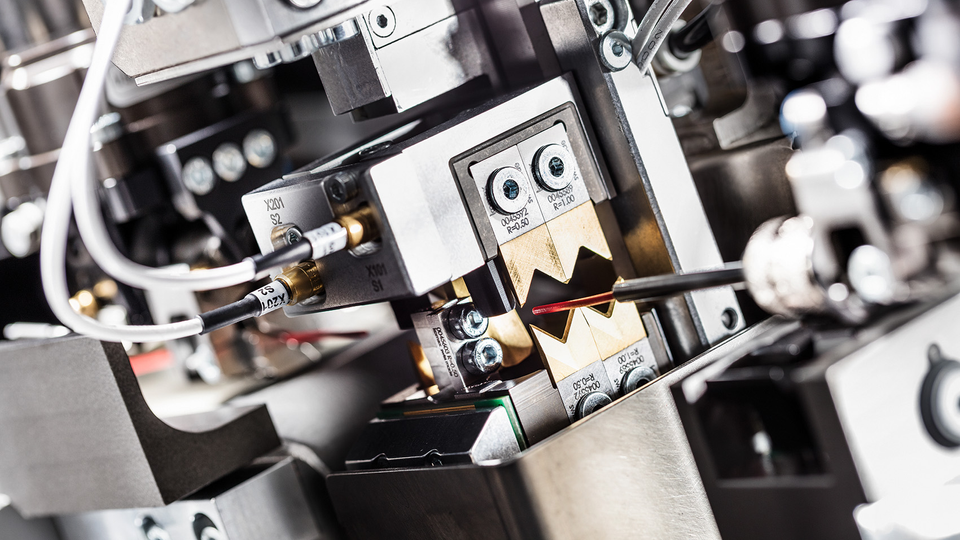

The Alpha 560 fully automatic wire processing machine is suitable for loading large terminals or seals up to a conductor cross section of 16 mm² on one or both sides.

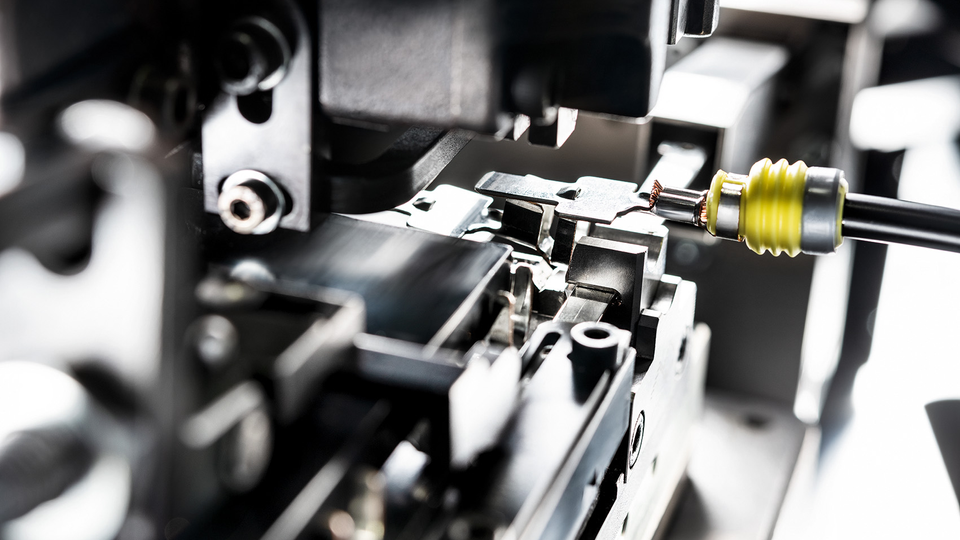

High-precision crimping process thanks to 50 kN crimp force

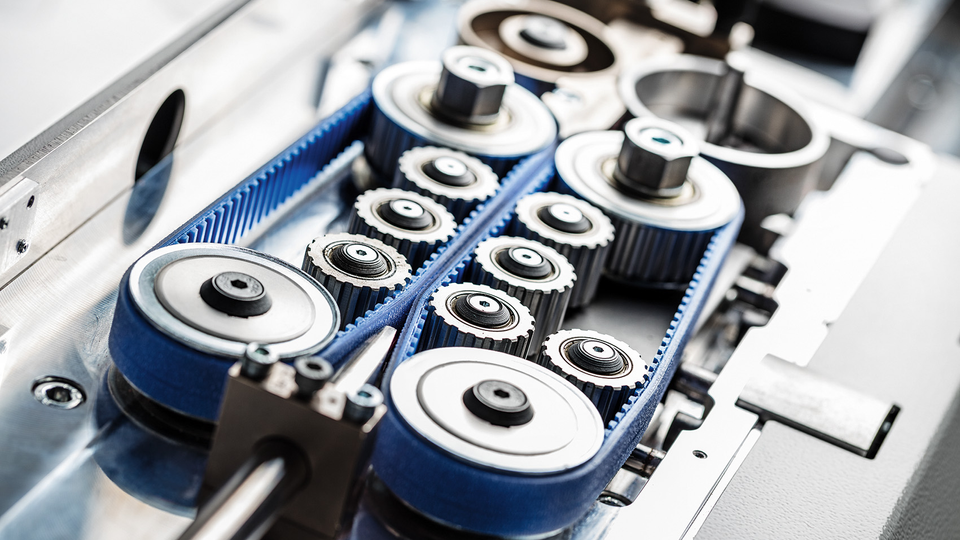

Efficient belt drive with 12m/s speed

Simple operation thanks to clearly structured processes in the Komax HMI

Two different blade radii thanks to the dual head double blade holder

| Specification name | Specification value |

|---|---|

| Wire cross section min. | 2.5 mm² |

| Wire cross section max. | 16.0 mm² |

| Wire length, single-sided processing min. | 60 mm |

| Wire length, processing on both sides min. | 60 mm |

| Wire length from 10 mm2/AWG8 min. | 100 mm |

| Wire length max. | 8000 mm |