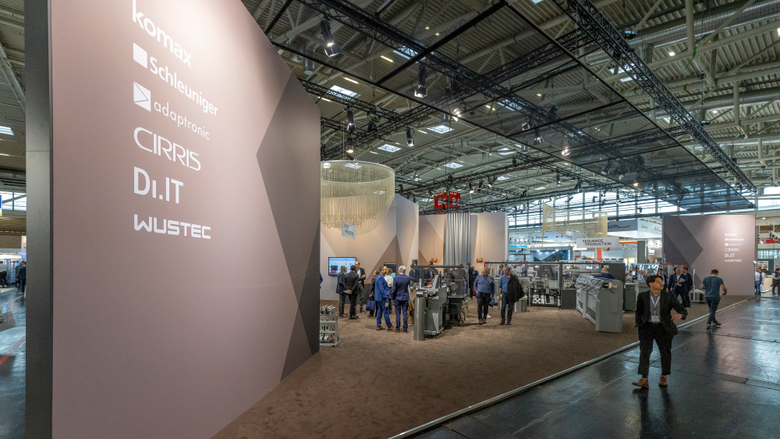

14 to 17 November 2023

productronica Munich

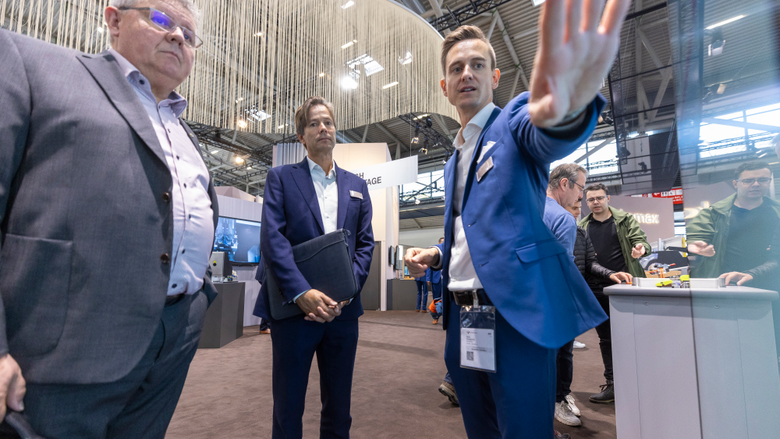

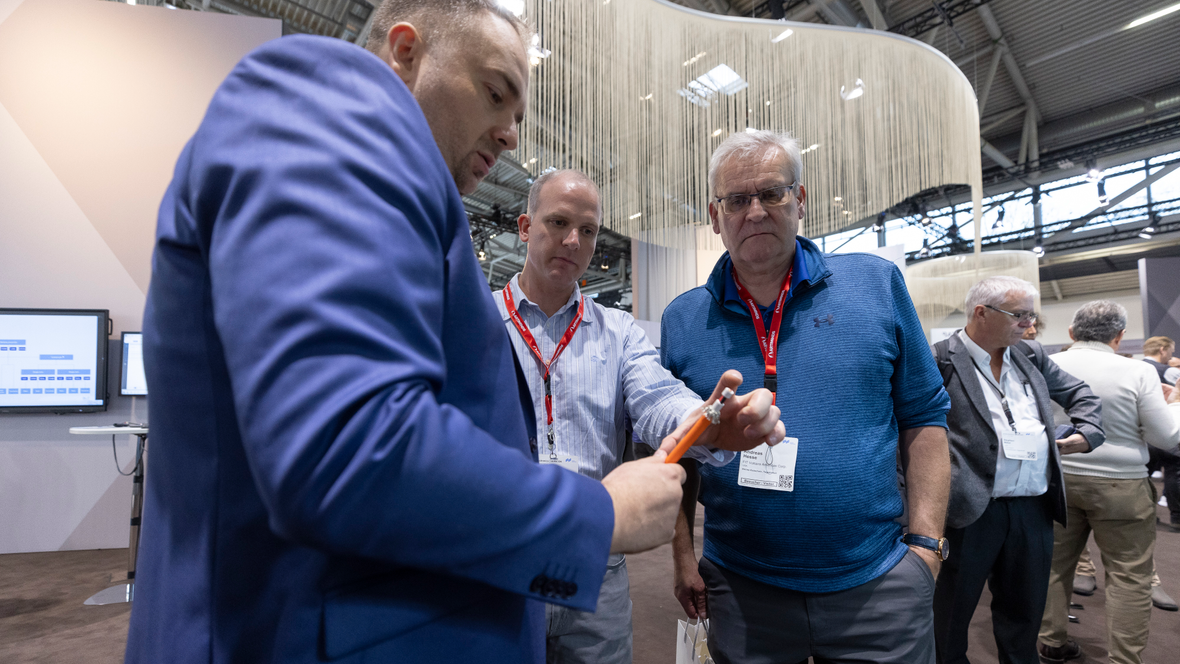

Thank you for visiting our booth in Munich! You saw the latest trends and innovations in wire processing live. Our concept is tailored to your individual requirements and needs. With our products and services, you can optimize, reduce, improve and increase your processes, costs and quality.

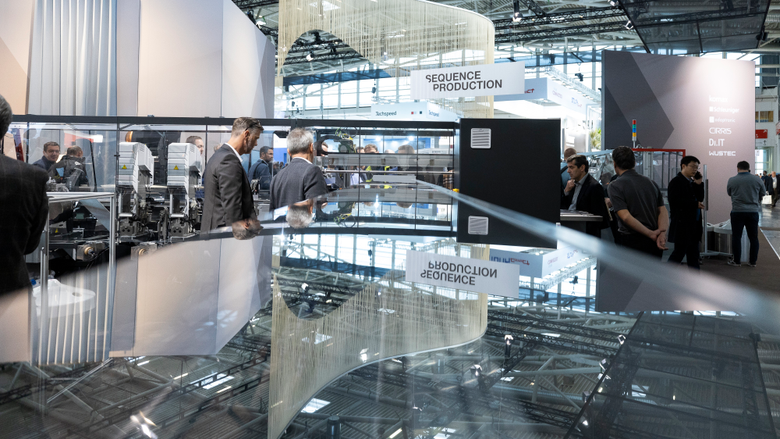

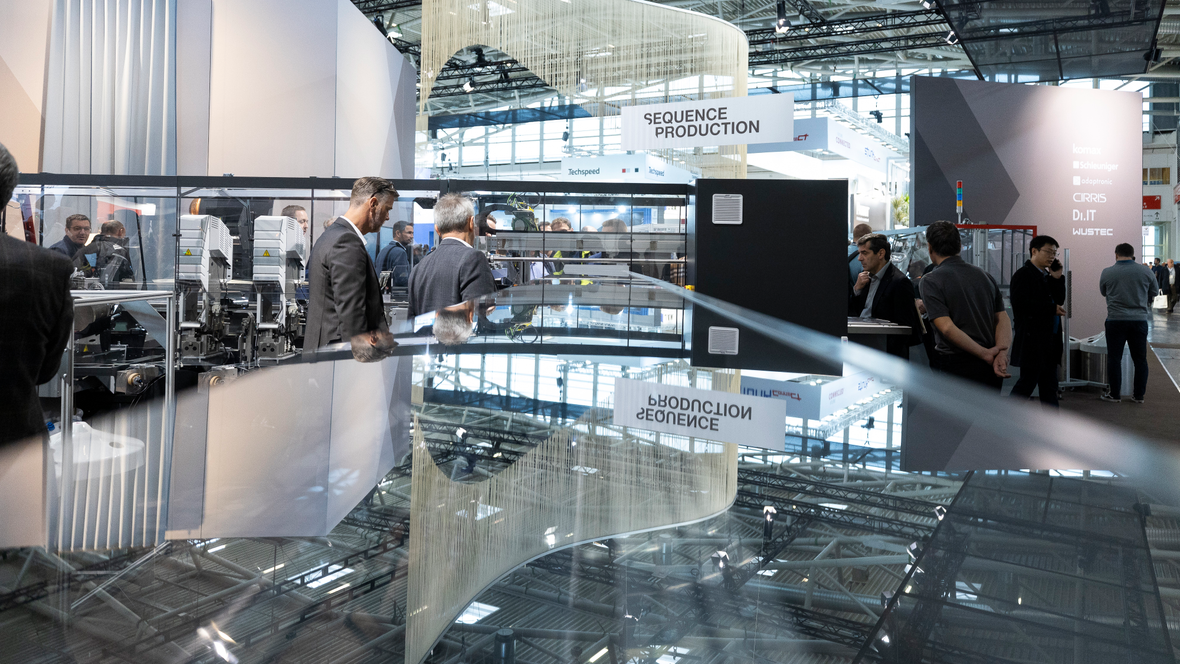

Sequence Production

With a one-piece-flow approach, different harness variants can be produced in sequence, according to the specifications. This offers many benefits, such as lower inventory levels, faster delivery time, and easy adaptation to design changes. It also guarantees full traceability of each harness.

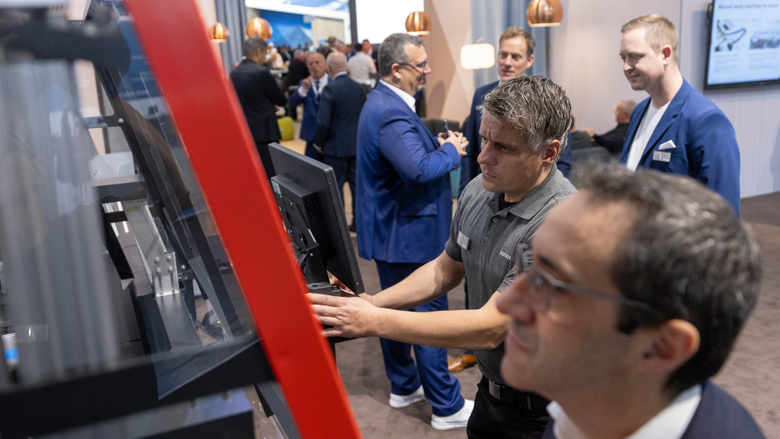

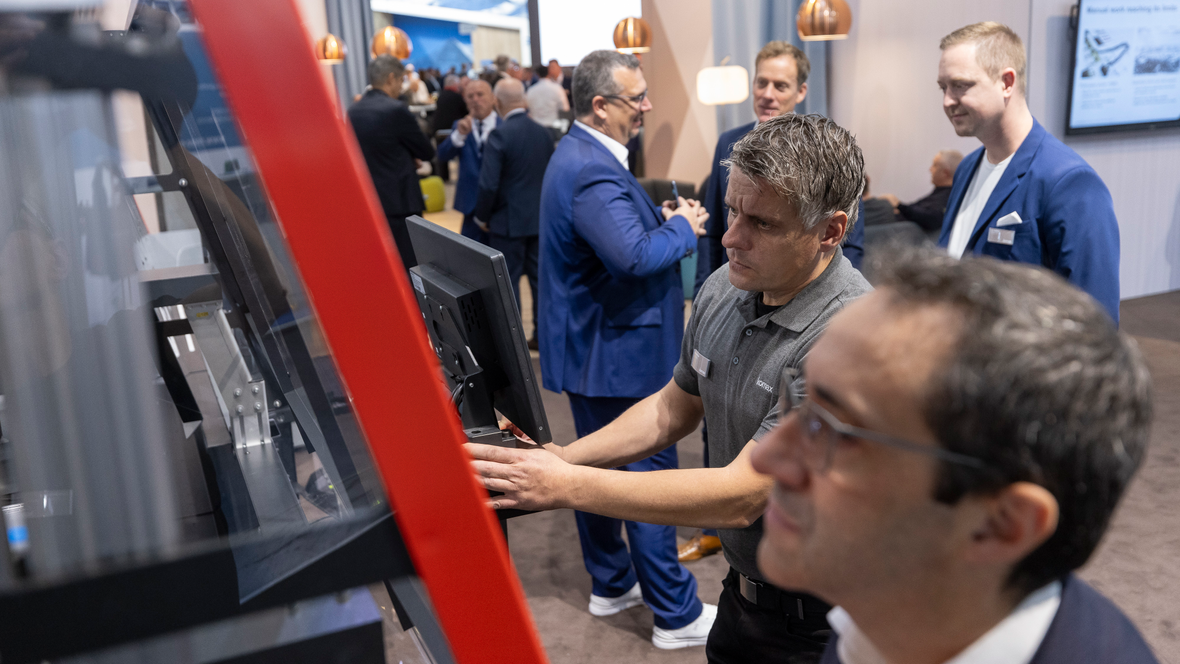

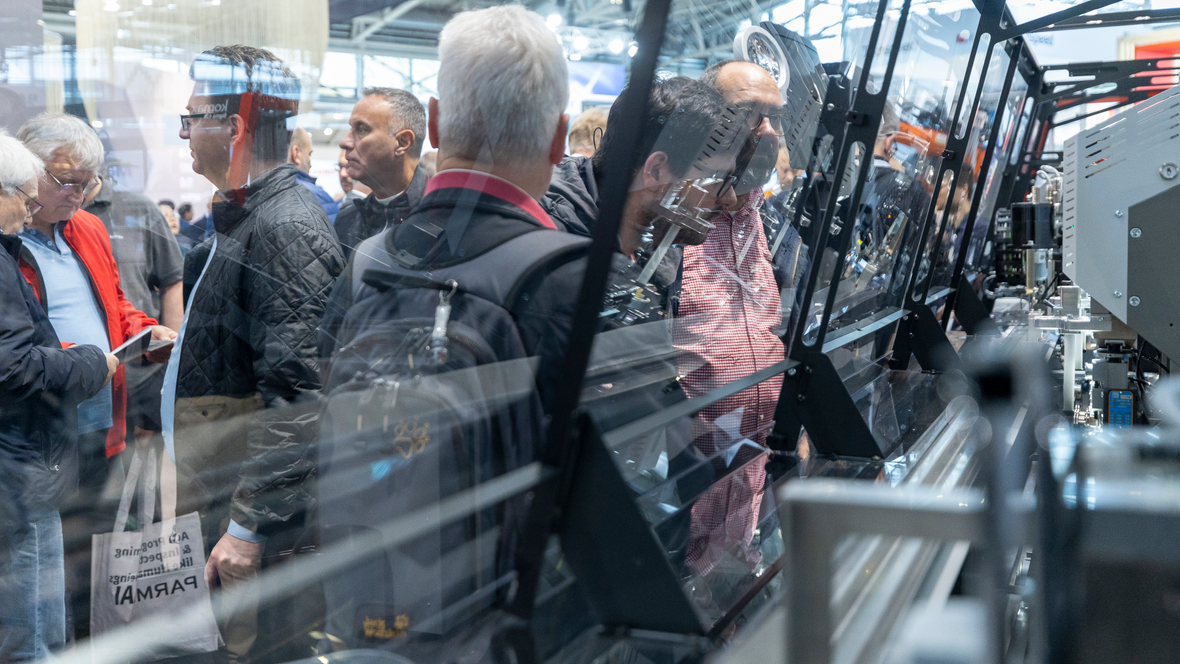

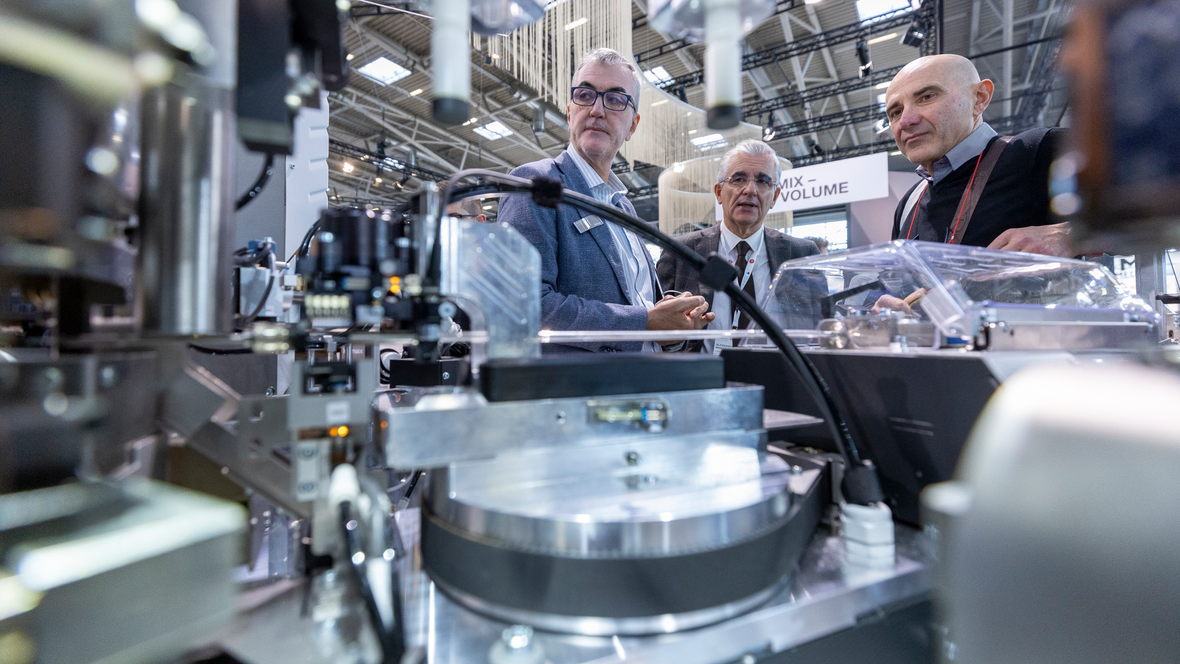

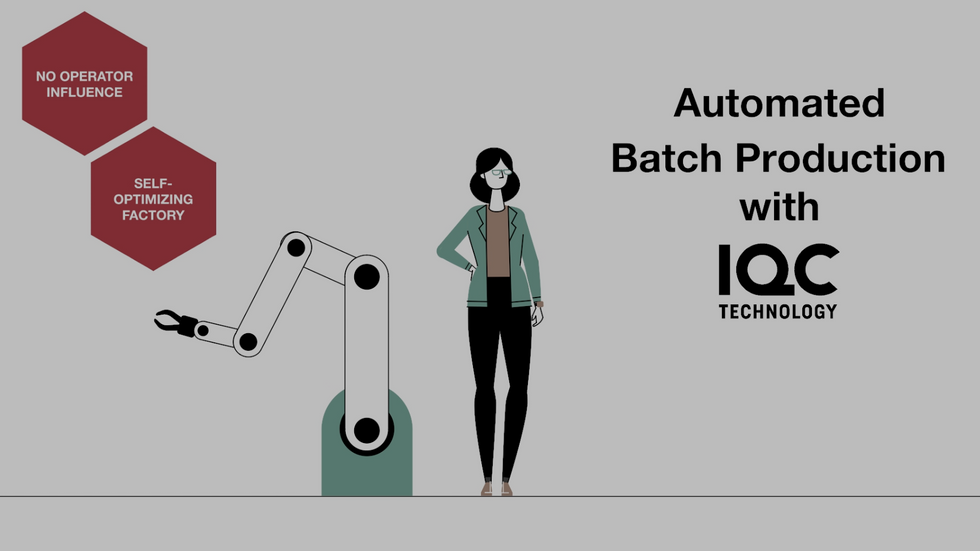

Batch Production with IQC Technology

IQC Technology facilitates efficient machine changeover, resulting in significant time savings. This technology enhances productivity by up to 50 %, minimizes errors due to human factors, and ensures high-quality results.

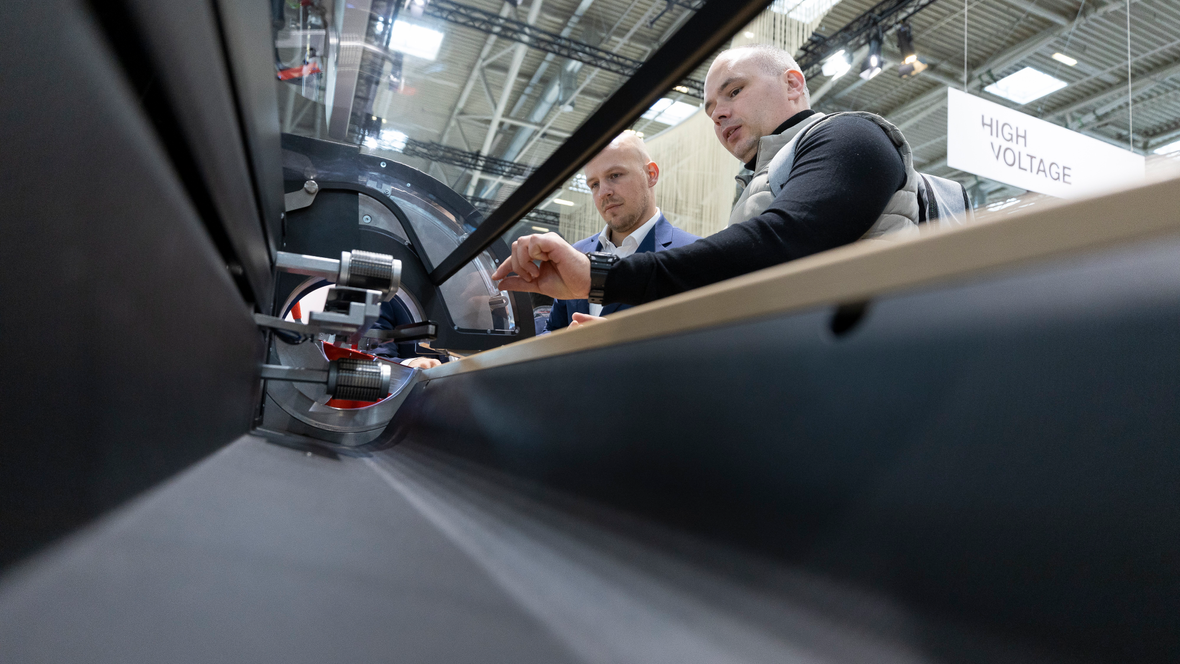

High Voltage

We cater to high production volumes by providing after-sales support and prototype production tools that meet the customer needs in the automotive industry and other sectors. We are currently analyzing the best-in-class products and process modules, and developing high-voltage platforms to the next generation.

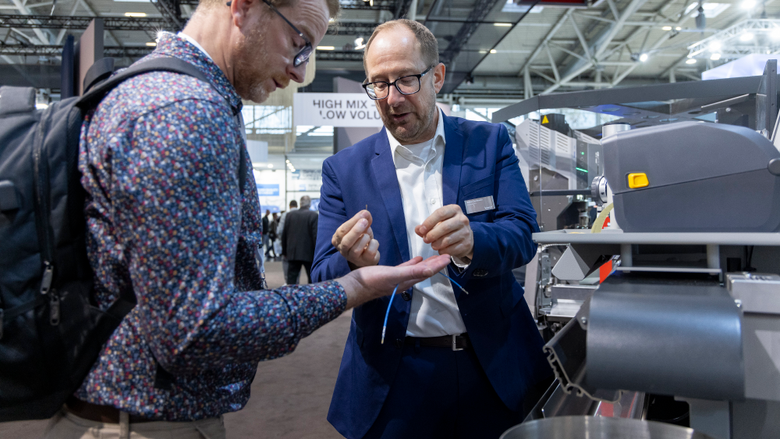

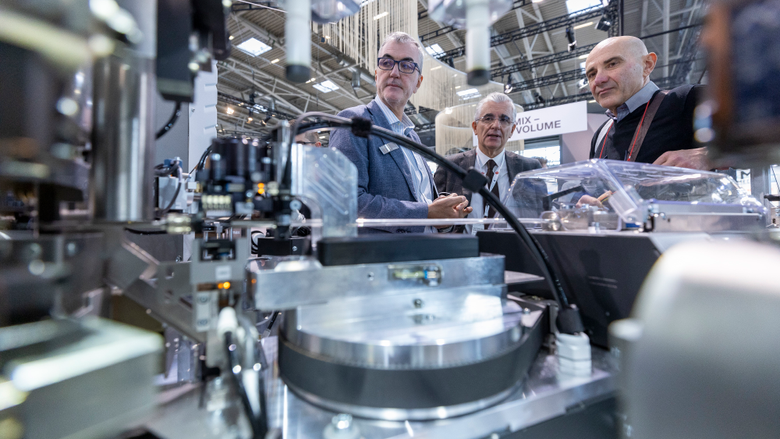

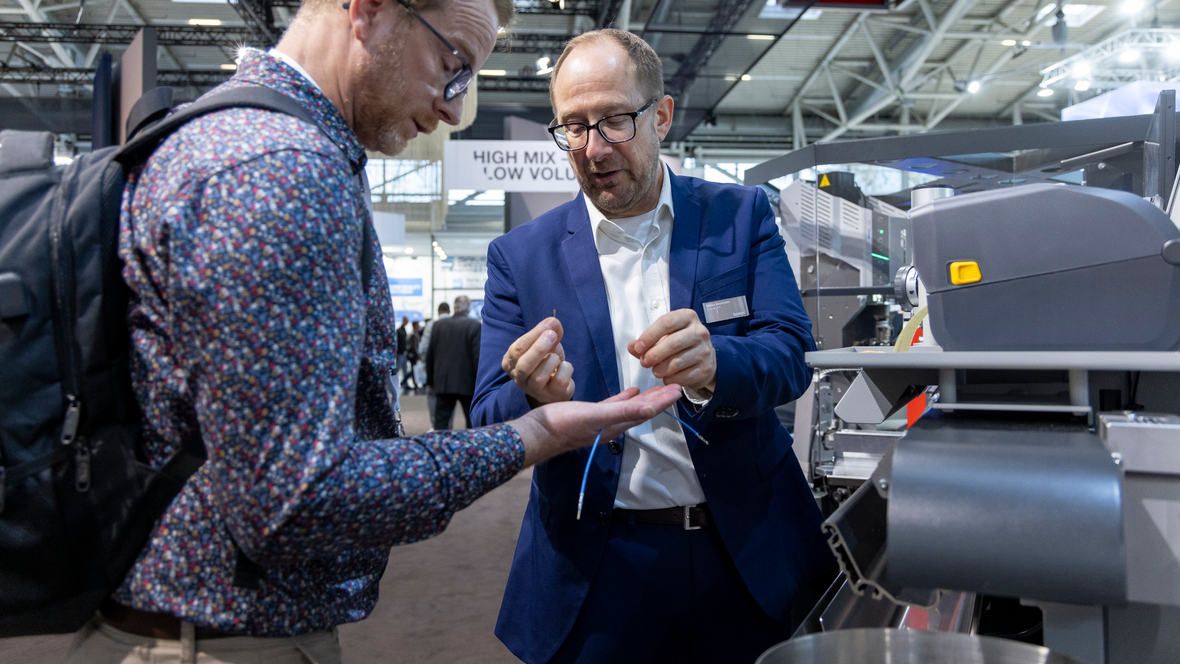

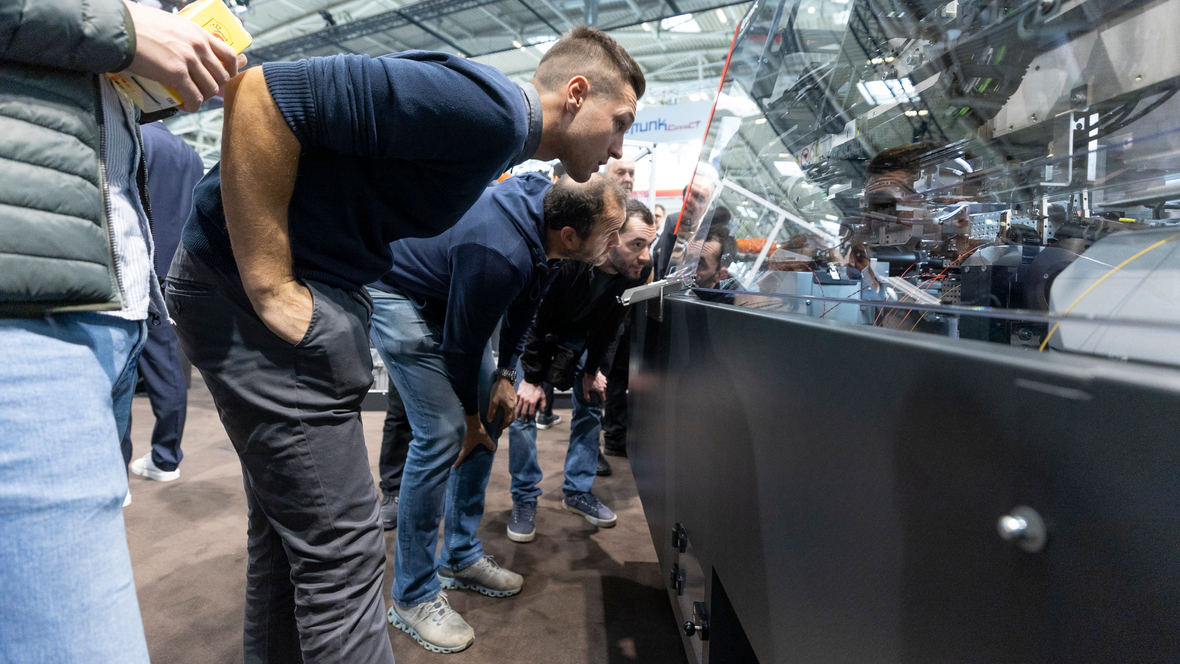

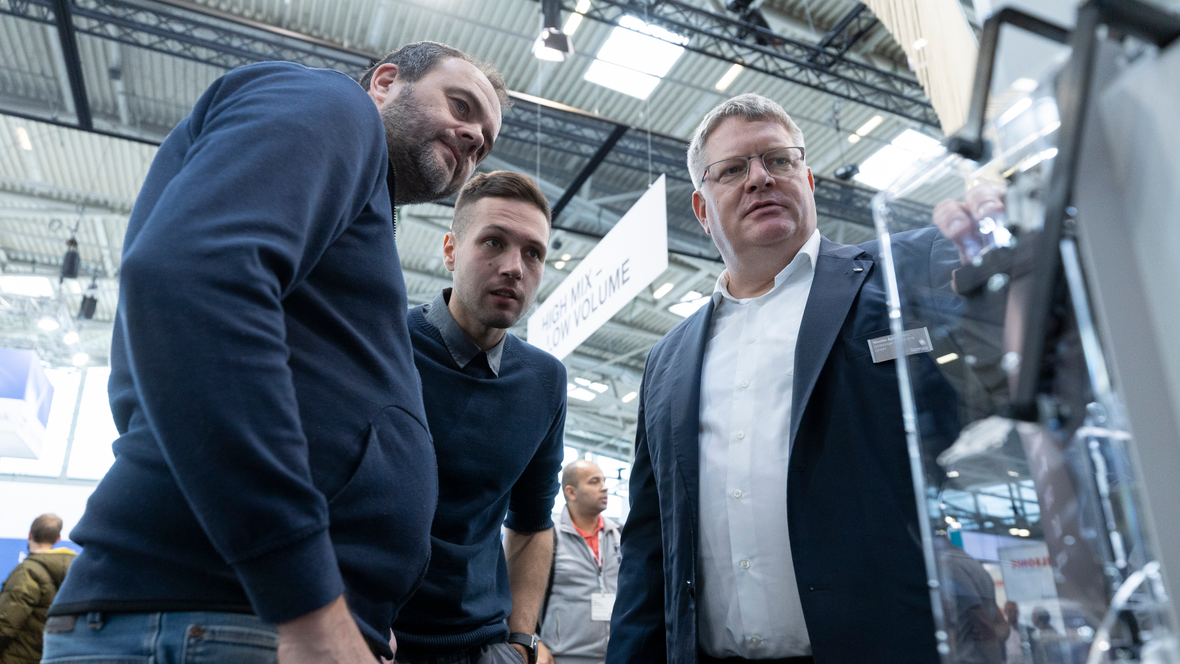

High Mix - Low Volume

Small and medium-sized cable assemblers rely on Komax Group for cutting-edge automation in diverse, small-batch applications. Our machines ensure high-speed, quality production with standardized interfaces for seamless networking and flexibility. Through digitization and automation, we boost productivity, offering tailored, cost-efficient systems for smart factory integration.

Services

At Komax, our comprehensive range of services is designed to enhance your roductivity and maximize the quality of Komax Group products. From product selection to installation, operation, and maintenance, we support you every step of the way. Our services are customer-centric, driven by your unique requirements.

Today, the production of wire harnesses is a major challenge for manufacturers. Rising wage costs abroad, more complex assembly options and uncertain supply chains are reasons for automating the production of wire harnesses. High quality requirements and 100 % traceability require new production concepts. Our “Quality at the first Go” approach enables you to meet these new market demands.

Discover our platform solutions to automate your production processes – all at once or step by step. The Smart Factory by Komax makes it possible!

High Voltage

High Mix – Low Volume

Sequence production

Batch production with IQC technology

Production Planning

To network your production machines, we present software specially designed for the requirements of wire processing. Comprehensive services from individually designed maintenance contracts to attractive financing models such as system leasing or rental open up flexible options for you.

Find out about customized and scalable production concepts – tailored to your requirements and budget. Discover how machines can be set up and converted automatically according to the “Plug & Produce” concept. Make your production highly efficient, networked and with minimal material loss. Achieve full transparency and measurable efficiency gains in the planning, control and traceability of your wire assembly processes.