New Push Pull Touch 2.0: More efficient testing of critical connectors

Technology & Innovation

The team at Komax Testing Germany has further developed the Push Pull Touch test system and taken it to a new level with the launch of version 2.0. Not only have the user-friendliness and system efficiency been improved, but the integration of new functionalities promises customers considerable advantages during the assembly process of critical connectors. They can look forward to a significant reduction in production time, better process control, lower costs, simplified final testing and overall higher production quality. Product Manager Eugénio Bonifácio tell us about it and explains what the Push Pull Touch 2.0 has to offer.

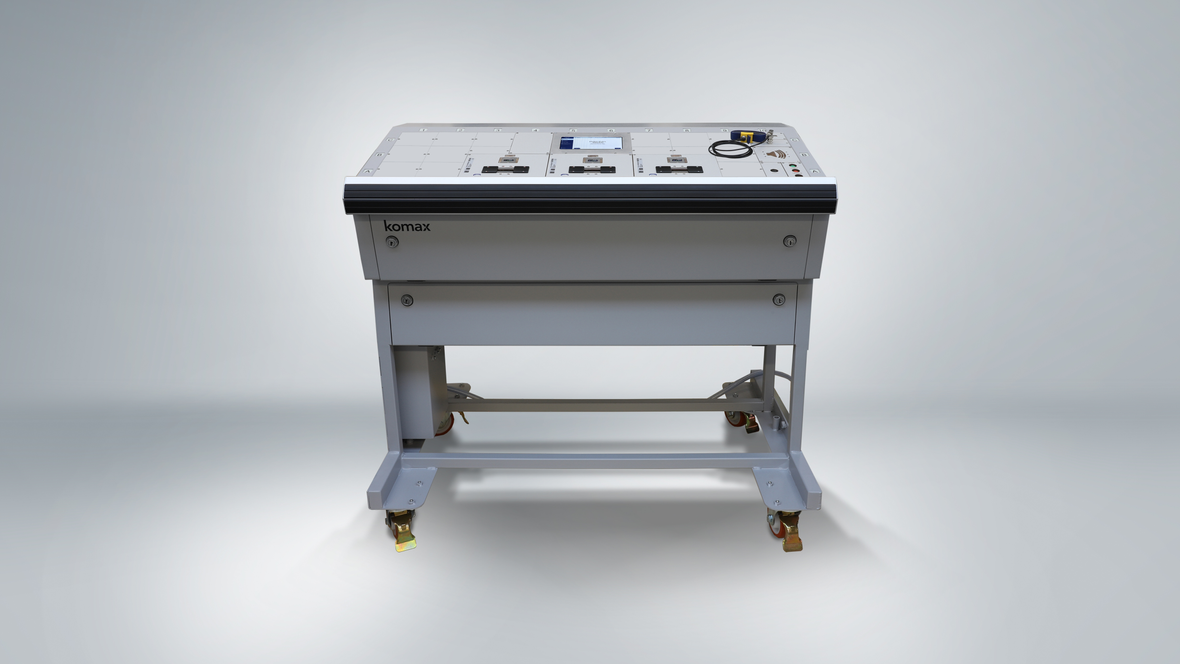

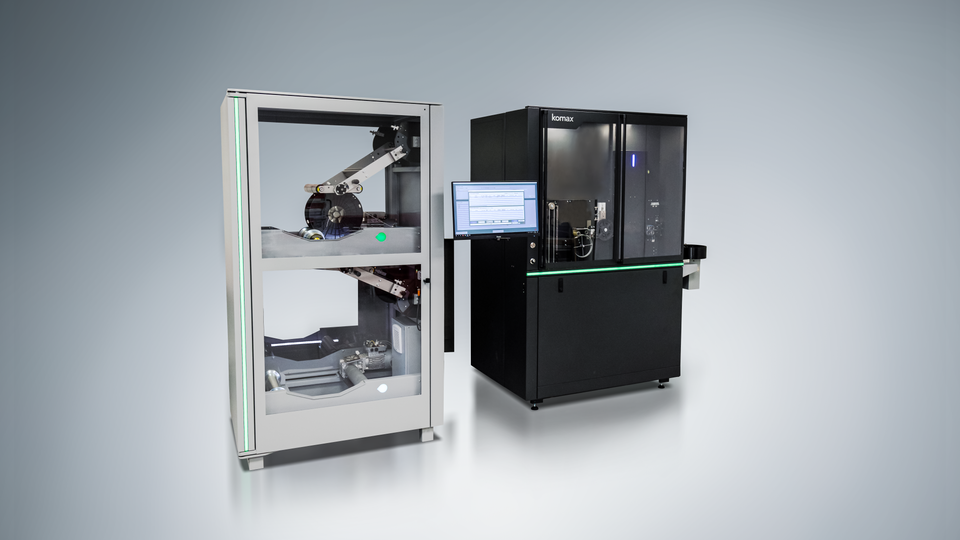

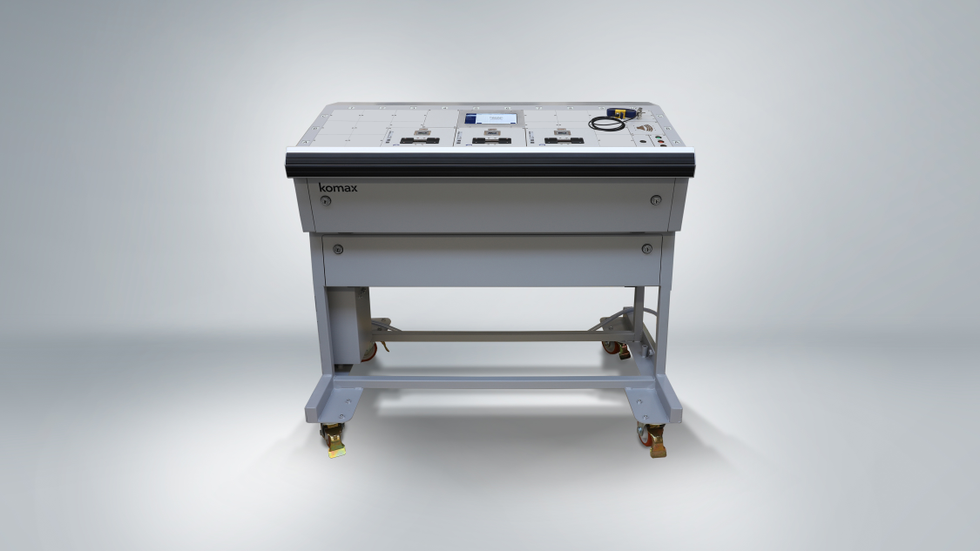

The automotive, aerospace and electronics industries are investing in smaller connectors for the production of wire harnesses and consequently in smaller wire terminals. Due to the minimalistic design of these parts, the typical manual assembly process requires devices with integrated push pull mechanisms that support fast and safe operation. As they must be tested both mechanically and electrically, they place high demands on quality assurance and therefore require an efficient and reliable testing process. This is ensured without exception by the Komax Group with the new Push Pull Touch 2.0 test system: “The integrated quality control ensures a 100% accurate assembly product by guaranteeing the correct positioning of the wires, the integrity of the terminals and their correct locking and alignment,” explains the responsible product manager, Eugénio Bonifácio from Komax Testing Germany. “The system is ideal for the quality control of wire assemblies and offers a user-friendly interface, assembly guidance supported by visual aids, force measurement and contact detection for accurate and safe wire insertion. For example, it inspects multiple test cases for both push and pull force measurement supported simultaneously with the EasyTouch function and can therefore comprehensively test the quality and functionality of wire assemblies on critical connectors such as Nano MQS and CMC/CMX series. In addition, the Push Pull Touch 2.0 has a modular design, allowing a high degree of flexibility and adaptability to different connector types and sizes.”

Additional safety and increased productivity

“With the Komax Testing Push Pull Touch 2.0, we have further developed its predecessor by strategically incorporating essential components into an IoT architecture and have thus expanded the range of solutions and services available to our customers,” continues Bonifácio. The software version 2.0 now includes a web server, responsible for configuration, and an HMI interface visualized on a display for the machine operator. Both are separate components within the system. Thanks to the low-code/no-code functionality, teams can create workflows by assembling pre-built software components, reducing the need for manual coding. Thanks to this approach and the integrated software toolkit, the application makes it easy to create test variants. Additionally, it is now possible to connect the Push Pull Touch 2.0 to ME systems. “The chamber LED helps to ensure 100% accurate and efficient placement of the wires in the connector, while the force measurement ensures that the appropriate force is applied during the push and pull process. An electronic wristband worn by the machine operator enables complete identification of each individual wire touched and the location of the connector housing chamber used. This provides additional safety, helps to avoid errors, and increases productivity.”

Multiple advantages for customers

In addition to the fact that the Push Pull Touch 2.0 leads to better quality in production thanks to the integrated quality inspection, it features advanced functions for optimizing wire assembly processes and thus supports customers in achieving their production goals. “Thanks to the improved process control, every work step is closely monitored. This prevents assembly errors, ensures consistent quality, and creates a more reliable and controlled production process,” explains Eugénio Bonifácio. But thatʾs not all: “The synchronization of the systemʾs interactive components – such as the follow-up instructions on the HMI, the speakers to indicate the transition of the test steps, the LED guide for the cavity, the pick-to-light system and the push and pull force measurement with EasyTouch – reduces the operatorʾs learning curve and ensures efficient and accurate placement of the wires in the respective connector cavities. As a result, the impact on increasing productivity through the entire error prevention mechanism is significant.”

“The precision and accuracy of the push-pull touch system also reduces the need for extensive testing after assembly and the time and effort required for final electrical testing of the wire harness during post-production.” Precise wire identification, on the other hand, is ensured by the wire touch technology, which combines touch-based input and interaction with precise identification of the wire in the correct connector cavity. “By integrating touch technology into the wire mating process, wire identification is possible even when the end of the wire is loose,” says Bonifácio. “Quality assurance is crucial during wire harness manufacturing, especially when it comes to inserting the terminals into the correct cavities to ensure a reliable electrical connection and avoid problems such as broken wires or loose connections. We were able to solve the problem of unseated terminals, which cannot be solved in typical applications due to mechanical limitations or the potential risk of damaging the terminal. By using our technology, we ensure that the terminal is properly seated during manual assembly.”

Configurable and with real-time feedback

The Push Pull Touch 2.0 can be easily adapted to specific requirements or preferences so that the operating personnel or administrators can make changes as required. For example, the configuration of different wire combinations, settings, parameters, or components can be customized. This adaptability ensures optimal performance and compatibility when applying different production requirements. “But also, the force measurement can be customized individually and for each wire,” explains Eugénio Bonifácio. “This multi-configuration feature provides optimal flexibility to test different scenarios within a single assembly sequence.” The continuous monitoring of push and pull force operations in combination with the contact check during the wire assembly also provides real-time feedback that enables immediate adjustments to be made, ensuring precise control over the assembly process.

“Because the Push Pull Touch 2.0 is a modular solution that incorporates multiple technologies, we can ensure connectivity and communication through embedded IoT objects that enable real-time data exchange and interaction between different components.” The Push Pull Touch 2.0 also has a lot to offer in terms of traceability thanks to reports with customer-specific test results and system monitoring, which additionally and continuously stores log data regarding the behavior of the system. “Numerous hours of research, development, testing and trial runs have gone into the development of our new test system so that we can offer our customers an excellent product with innovative functions,” explains Bonifácio, adding: “The Push Pull Touch 2.0 gives us a big head start over our competitors and fills the gap for our customersʾ needs in terms of inline testing, which is increasingly becoming a must in product quality assurance again.”

Contact

Eugénio Bonifácio has been Product Manager at Komax Testing GmbH since 2019 and acts in his role as a central hub, actively collaborating with R&D, sales, external partners and customers. He has a three-decade background in the automotive industry and has held various technical positions in the past, including Test Systems Engineer and R&D Assistant Manager/Application Manager.