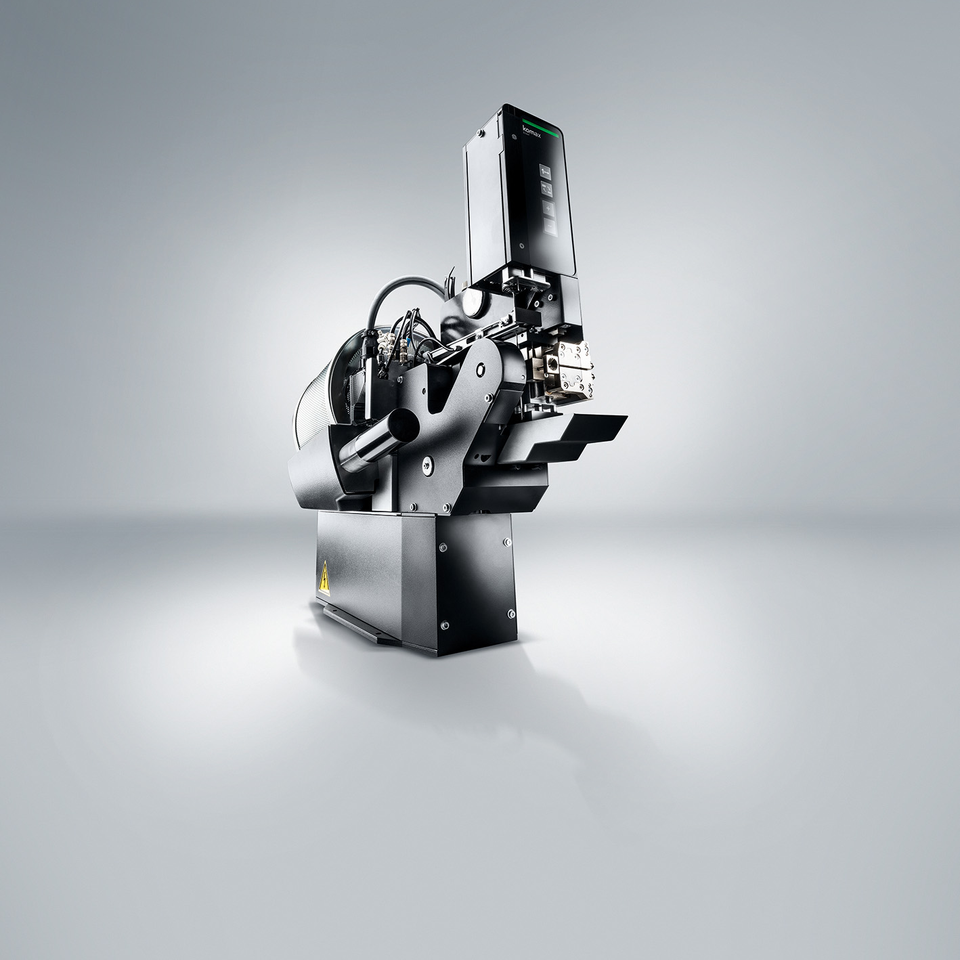

附加功能,如自动二次锁

单独开发的工具可以自动关闭插头外壳的二次锁装置。该工具可作为附加功能集成。

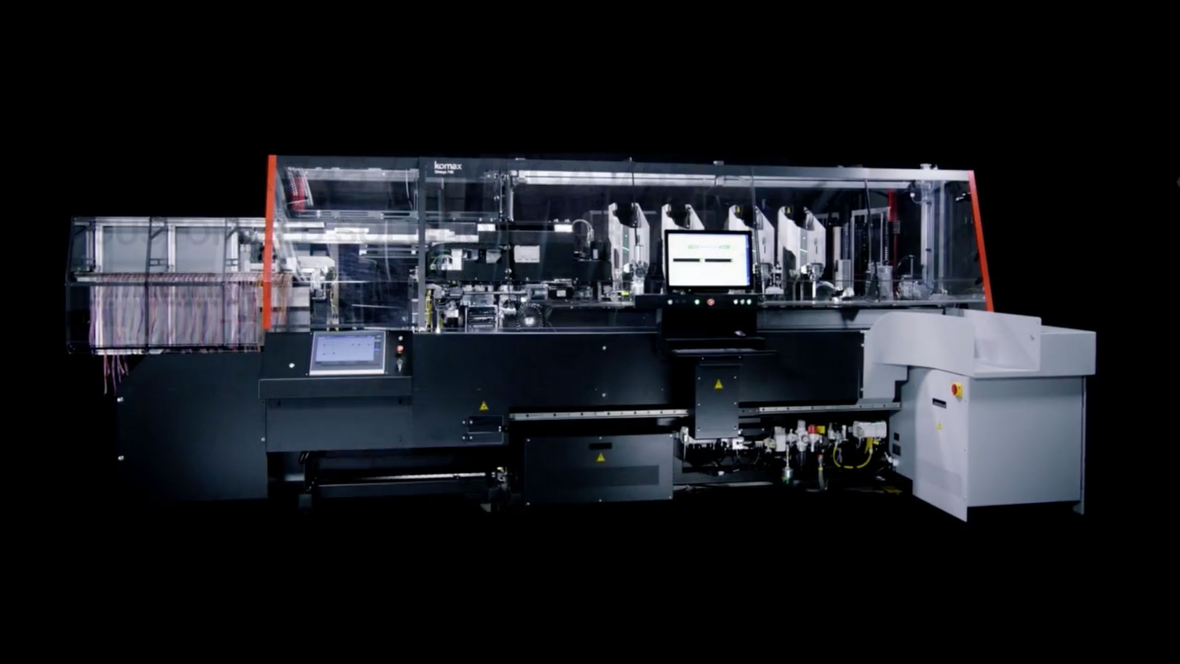

灵活的外壳轨道系统确保不间断生产

最多可同时为四种不同的护套提供能量。这可确保在机器运行期间高效地装卸外壳和成品线束。

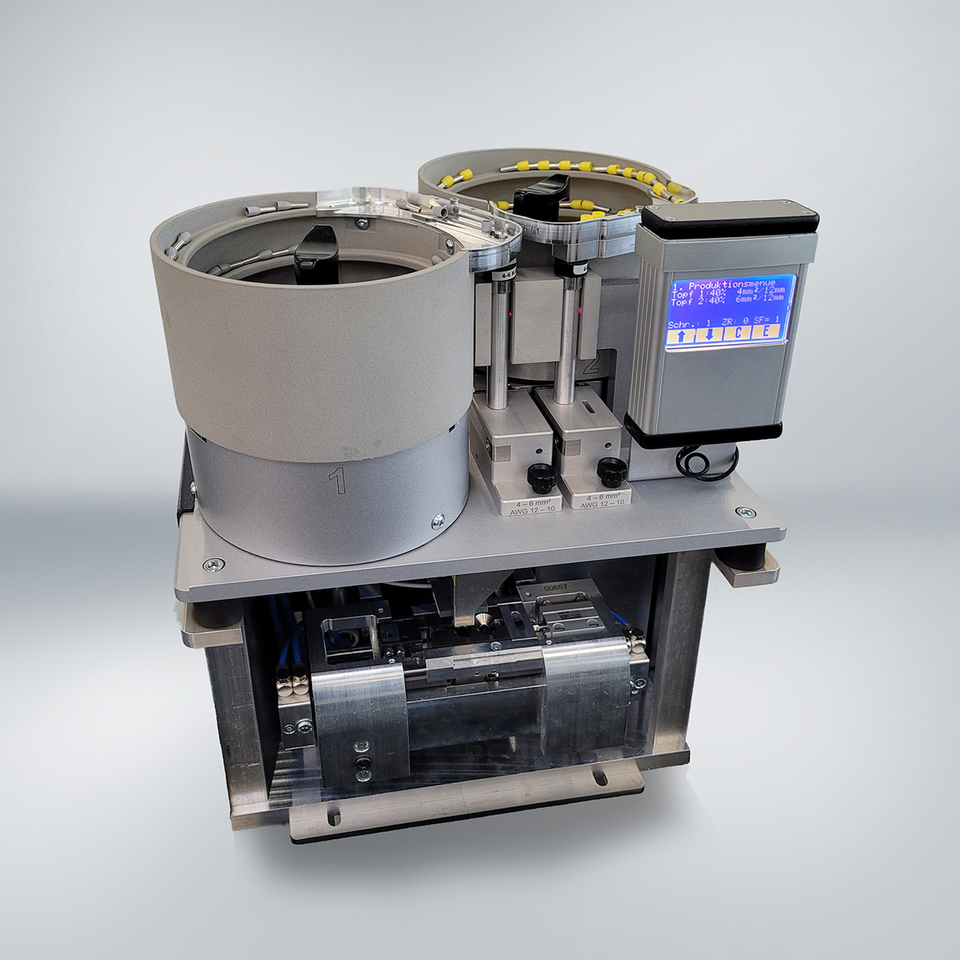

通过力传感器监控插入过程

接线端子外壳被送入轨道。插入式夹具监控插入力并检查端子是否正确锁定。

在继续生产之前,暂时存放线束

成品线束被收集在任意长度的定制轨道中,直到操作员将其卸载以供进一步处理。

| Specification name | Specification value |

|---|---|

| 单头加工的最短线长 | 240 mm |

| 最短线长,双面跳线连接 | 300 mm |

| 最短线长,两端跳线连接最大值 | 540 mm |

| 最短线长,最小复杂加载 | 300 mm |

| 最短的线长,最大复杂加载 | 760 mm |

| 最大线长(标准托盘) | 3000 mm |