Wire Stripper

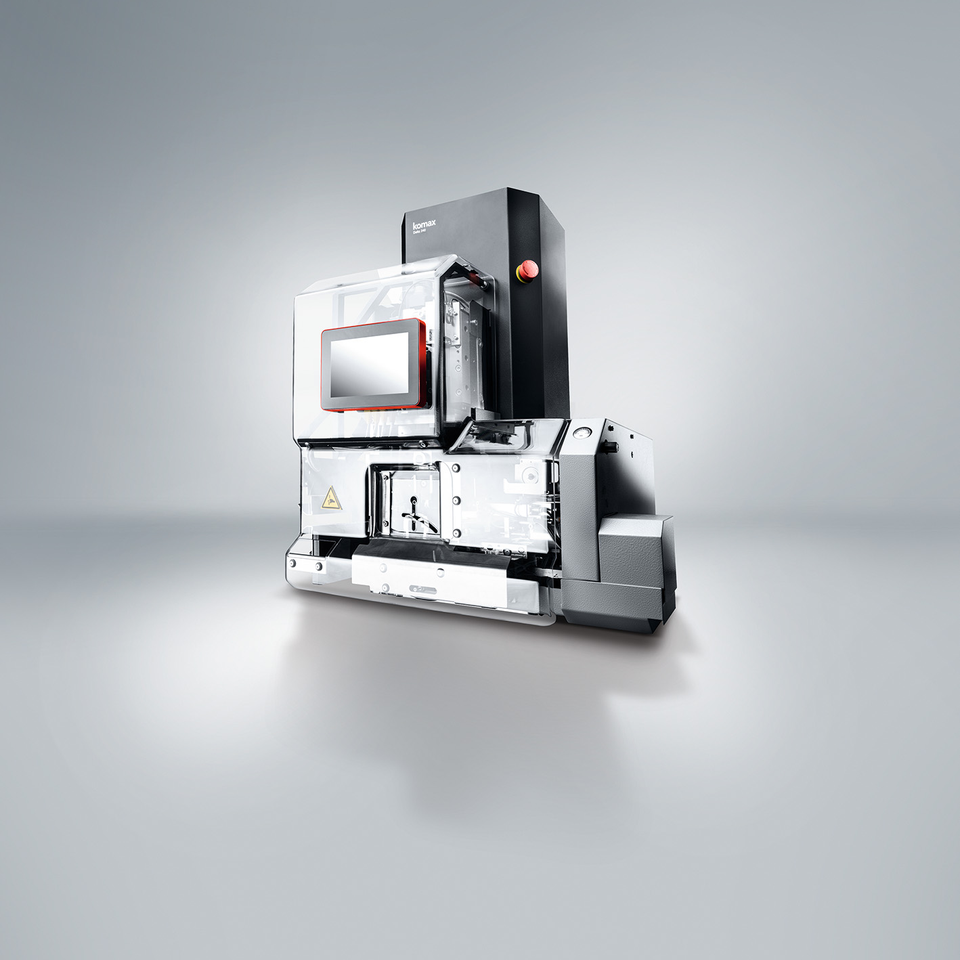

Mira 230

The Mira 230 enables precise stripping and cutting of various wire specifications up to 6.5 mm outer diameter and 46 mm strip length.

Easy to transport thanks to ergonomic handle

The convenient handle on the upper housing makes the portable Mira 230 wire stripper easy to transport, like all Komax wire strippers.

Full quality control with ACD incision monitoring

The ACD incision monitoring system of the Mira 230 Q detects and signals the slightest contact between the blade and strands for fully-automatic quality control.

Ergonomic working position thanks to hand rest and draw-in

A comfortable, mobile hand rest is included with the Mira 230. This and the low-lying wire line go easy on operator posture.

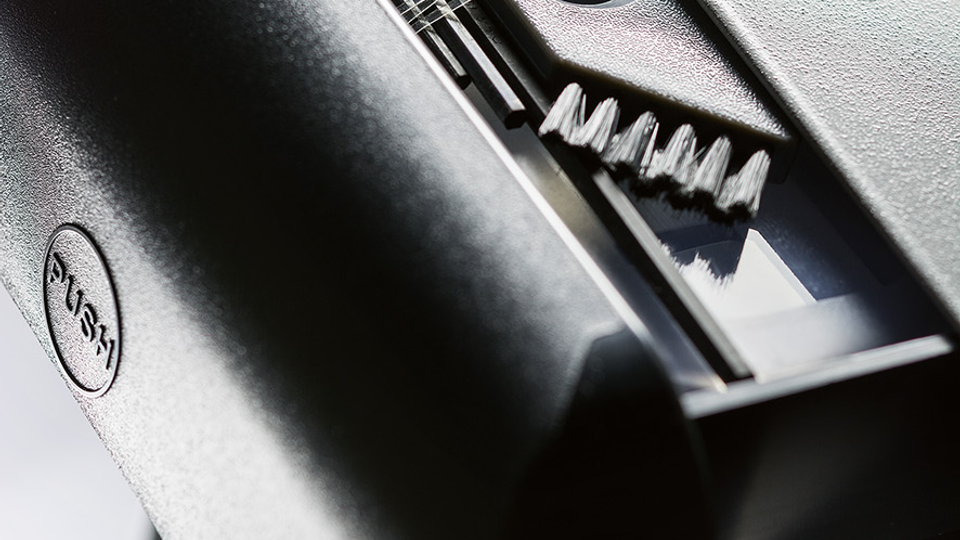

Built-in accessory drawer on the back of the device

The accessory drawer on the back can be opened by pressing and provides neat and orderly storage for all key tools of the Mira 230.

| Specification name | Specification value |

|---|---|

| Wire outer diameter max. | 6.5 mm |

| Strip lengths, full stripping max. | 46 mm |

| Increment of strip length | 0.01 mm |

| Insertion depth with standard grippers min. | 11 mm |

| Insertion depth with optional thin grippers min. | 8 mm |

| Number of entries in the article library | 1500 |