QCenter

QCenter

The QCenter software integrates the crimp height and pull-out force measurement devices into the production process and only releases production if the target and actual values match.

Modular system

Experience Flexibility

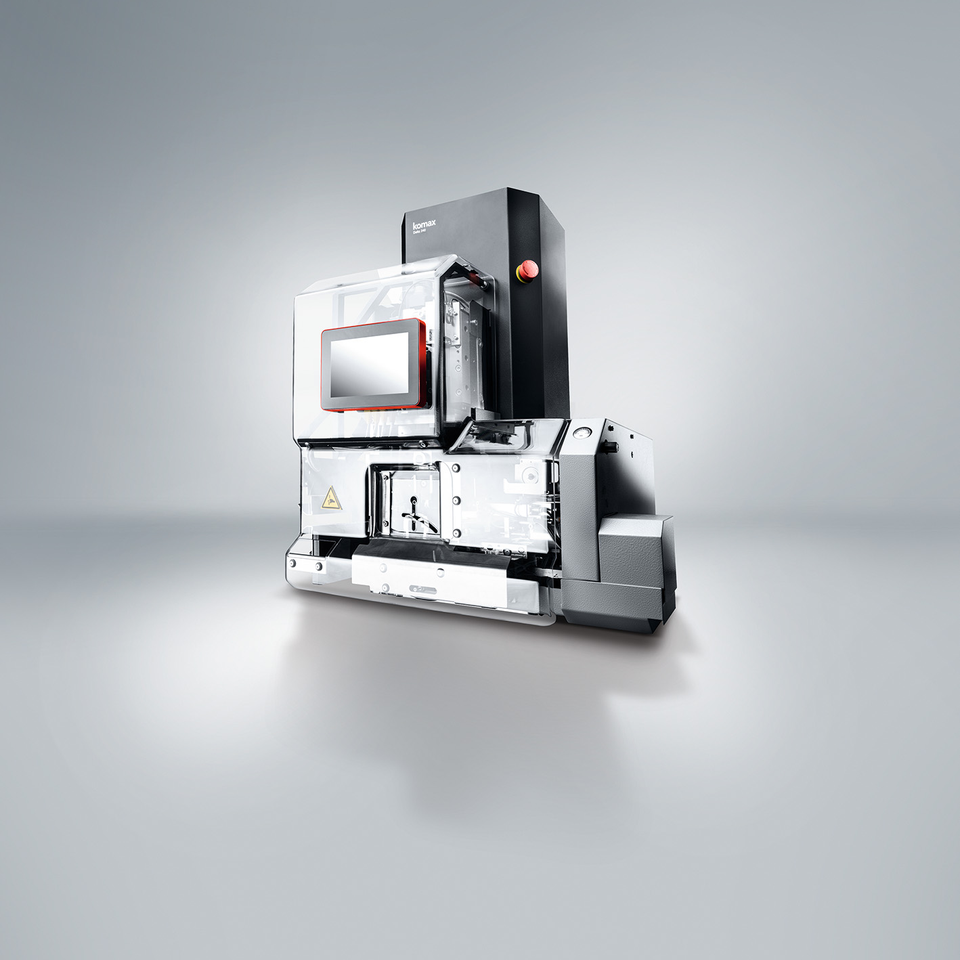

Crimper

Delta 220

The basic Delta 220 model is a programmable crimping machine with crimp force monitoring and manual crimp height adjustment – optionally with stripping unit and bad contact cutter.Learn moreCrimper

Delta 240

The Delta 240 semi-automatic crimping machine with crimp force monitoring offers automatic crimp height adjustment and stripping unit – optionally with bad contact cutter.Learn moreCrimper

Delta 260

The programmable Delta 260 can place a seal, strip the wire and crimp a terminal in one cycle. It offers crimp force monitoring, automatic crimp height adjustment and a bad contact cutter.Learn moreQuality Tools

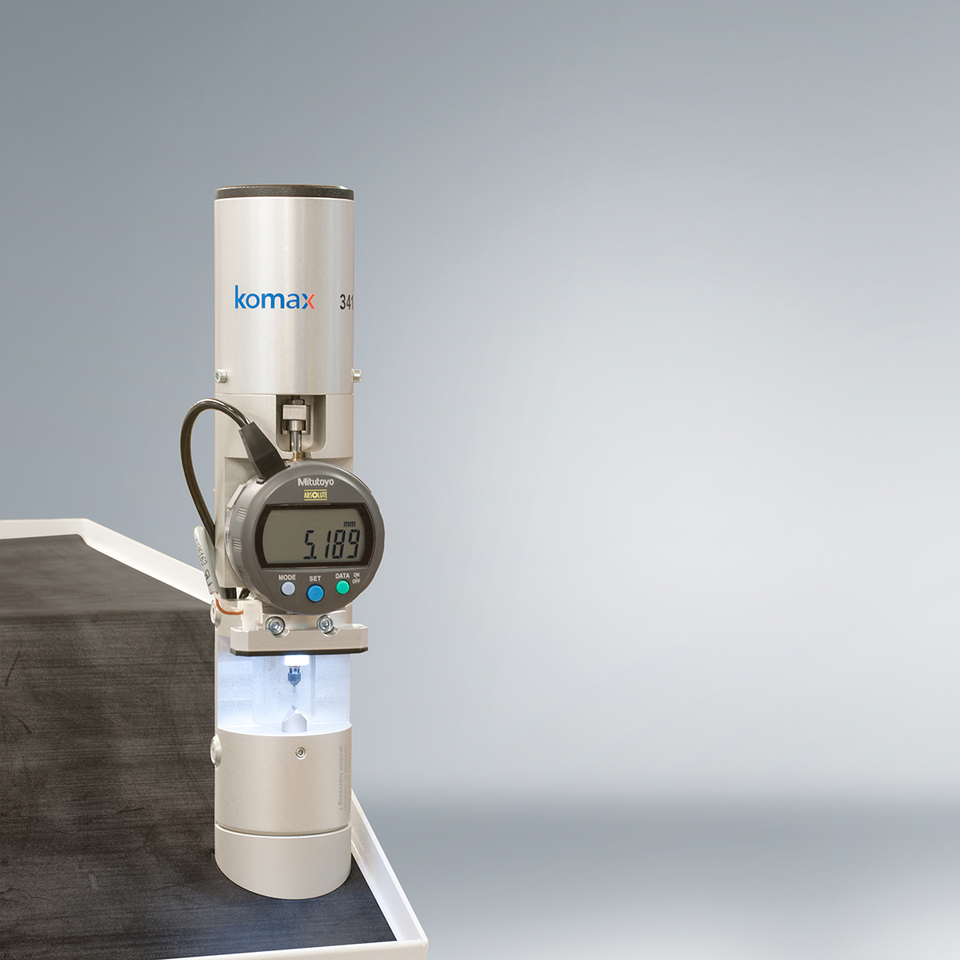

Komax 341

The Komax 341 crimp height measurement device measures terminals up to a height of 8 mm and compares them with the target crimp height. If there is no match, production will not start.Learn moreQuality Tools

Komax 345

The high-quality, digital Komax 345 microscope enables the control of stripping and crimping quality, even with miniature terminals and the smallest wire cross sections.Learn moreQuality Tools

Q1210

The Q1210 precision measuring module for wire processing machines measures pull-out forces of 20 to 1000 N with a pull-out speed of up to 200mm / min.Learn more

Downloads

Related products

Browse alternatives

Software and NetworkingTopConvert

The TopConvert software translates CSV data into WPCS format (Wire Processing Communication Standard) to easily load entire cutting lists into wire processing machines.

Software and NetworkingDLW

The DLW software supports qualified personnel in preparing production data for automated prefabrication of wires in a practical and efficient manner, even from batch size 1.

Software and NetworkingKomax Cloud MES

The Komax Cloud MES, which is specialized for the cutting room, sends complete product data, monitors production and evaluates machine feedback conveniently and cost-effectively.

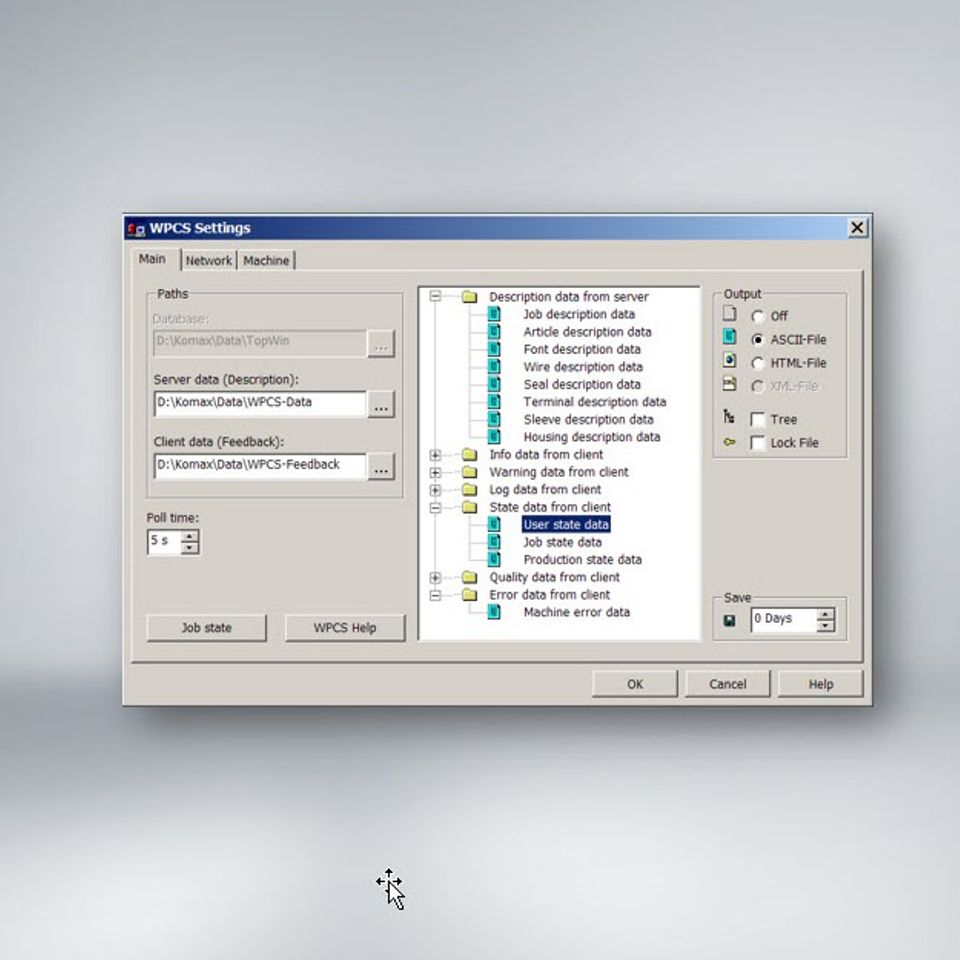

Software and NetworkingWPCS

The WPCS (Wire Processing Communication Standard) is a flexible interface that enables the simple networking of fully automatic wire processing machines.

Software and NetworkingMIKO

The MIKO interface enables real-time data exchange between wire processing machines and client systems, such as production planning and control systems.