Quality Tools

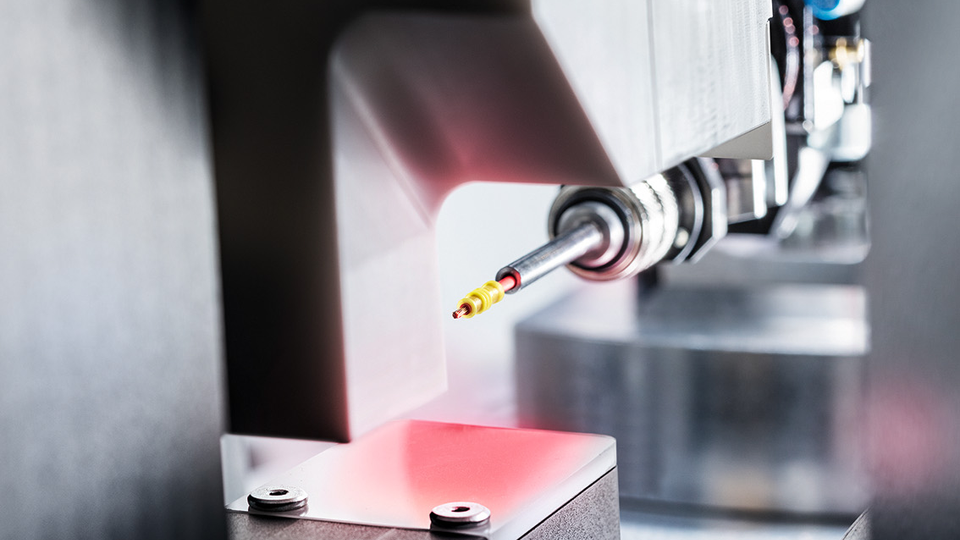

Q1250 scalable

As a basic version, the scalable Q1250 module offers testing of the stripping as well as the crimp and seal. All quality features are comprehensively tested in the full package.

Scalable digital wire end detection

The Q1250 offers appropriate crimp monitoring for every requirement. If the requirements change, the module can be easily upgraded with additional licences and/or the dome light.

| Specification name | Specification value |

|---|---|

| Strip length with full or partial stripping max. | 18 mm |

| Camera coverage | 24 x 16 mm |

| Restrictions on use | Can be used in combination with a tinning module, on request. If the Q1250 is used together with a tinning module, a protective cover must be used. |

| Dimensions/length | 90 mm |

| Dimensions/width | 290 mm |

| Dimensions/height | 524 mm |