Marking Systems

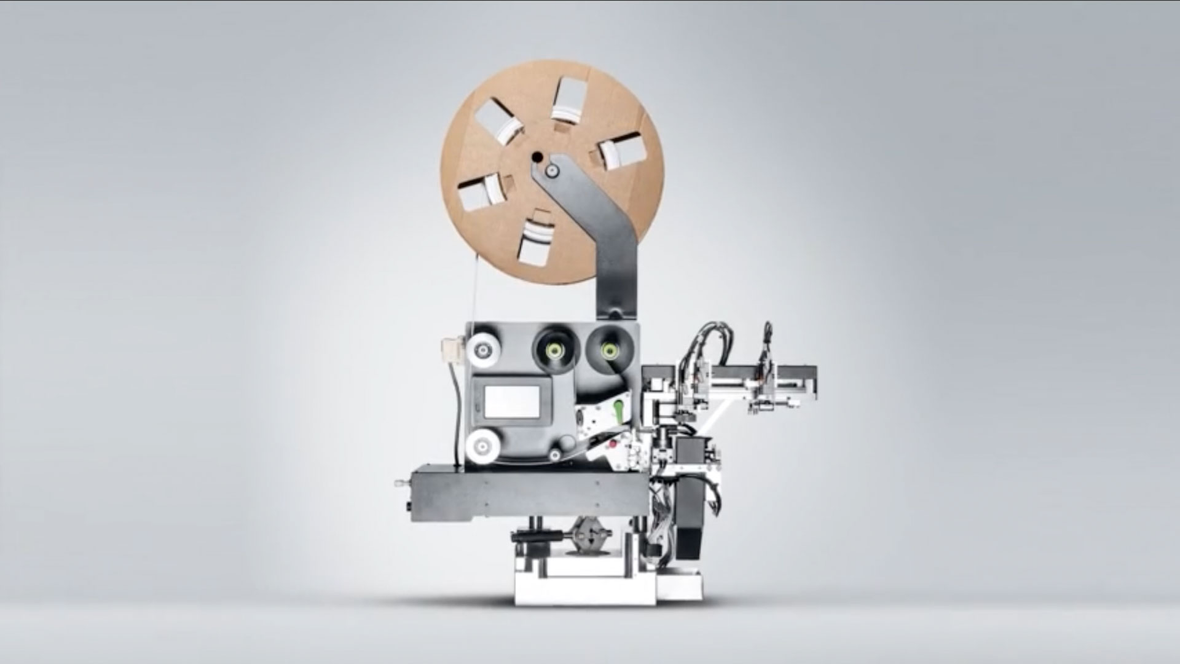

M1650 Tube

The M1650 tube marking module prints marker tubes and pushes them onto the wire. The module is designed for machines in the new Zeta 6x0 range.

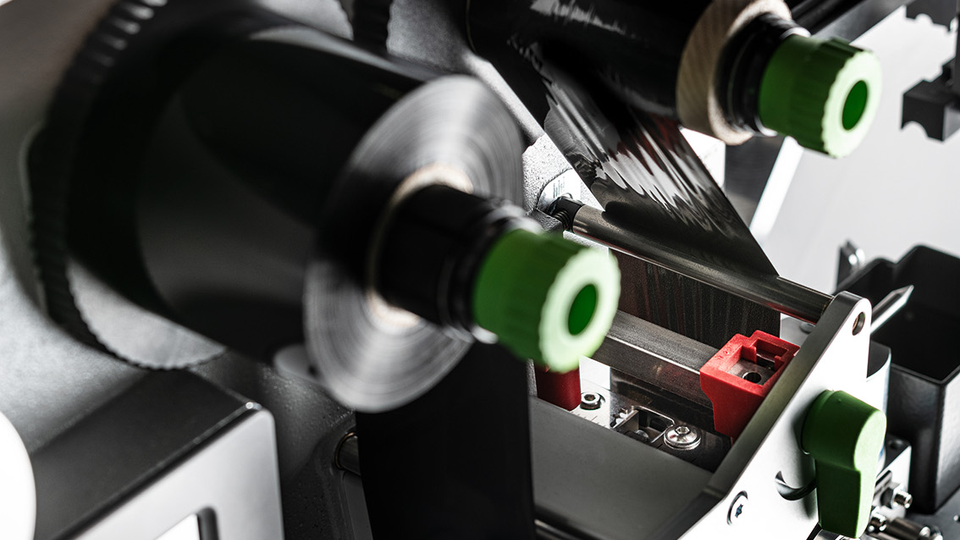

Reliable color marking with thermal transfer marking unit

Tube marking offers high abrasion resistance thanks to the thermal transfer marking process. High contrast for clear legibility is provided regardless of the conductor color.

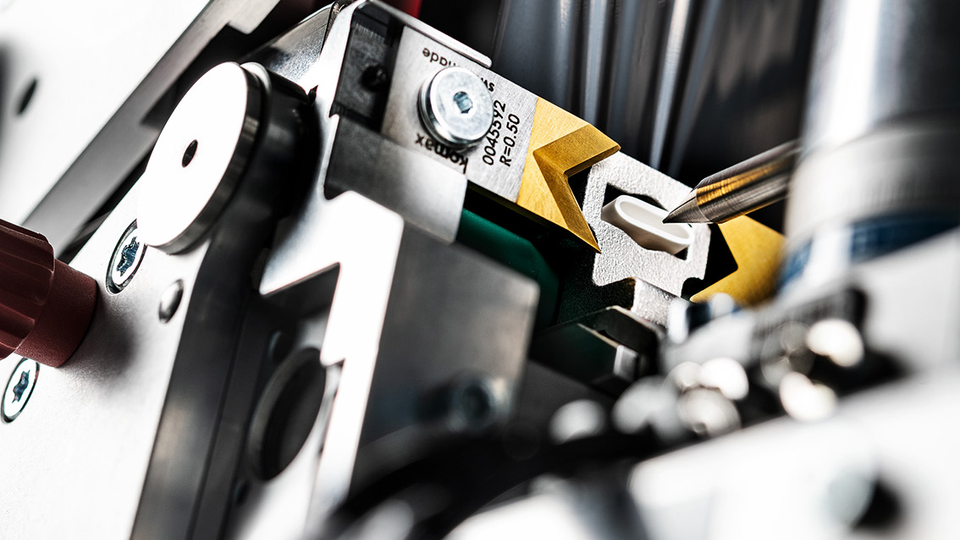

Precise placement of tubes on the cable using a mandrel

The identification hose is inscribed, cut and then pushed onto a mandrel where the gripper takes over.

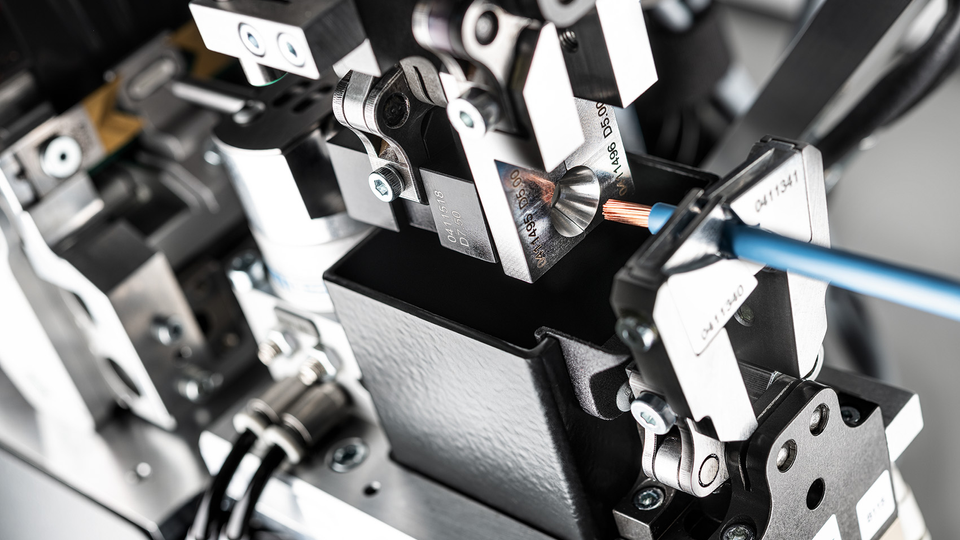

Precise placement of the tube over the wire thanks to a funnel

The tube is prepared by the grippers for pushing onto the wire. Finally, the tube is pushed over the wire via the gripper unit with a funnel.

| Specification name | Specification value |

|---|---|

| Tube length Omega 7xx (depending on tube material and insertion position of terminal) max. | 27 mm |

| Tube length Omega 7xx (depending on tube material and insertion position of terminal) min. | 10 mm |

| Wire cross section min. | 0.5 mm² |

| Wire cross section max. | 6 mm² |

| Cycle time | 1.9 sec./tube |

| Tube length Zeta 6x0 (depending on tube material) min. | 10 mm |