Cut and Strip

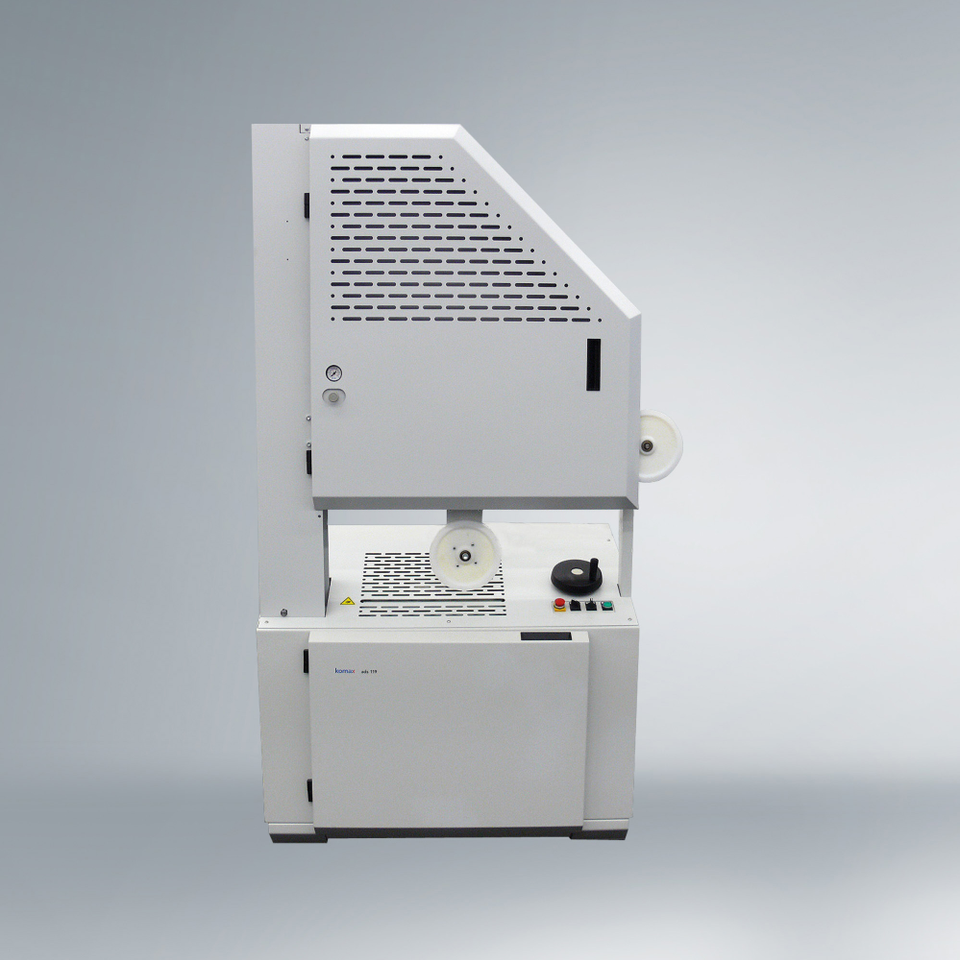

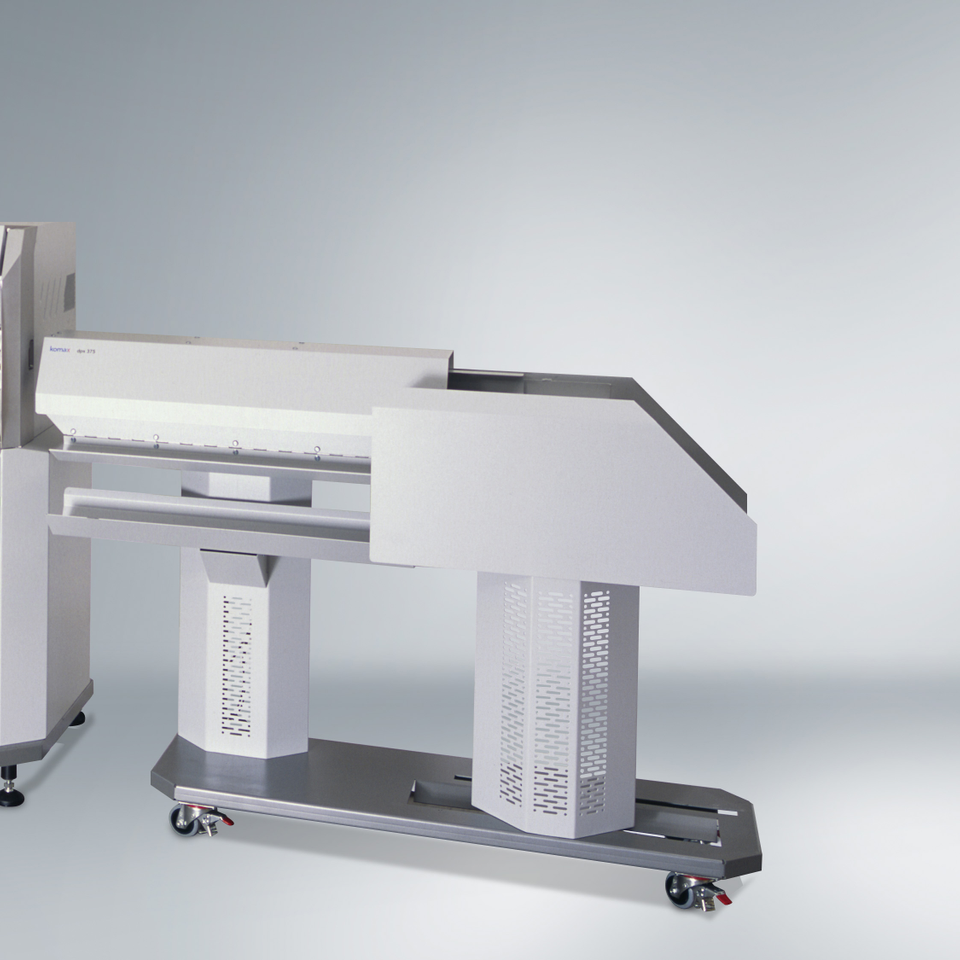

Kappa 350

The Kappa 350 cutting and stripping machine processes round conductors up to 120 mm² and a maximum outer diameter of 35 mm in high quality thanks to sophisticated sensors .

Precision and high quality for many processing areas

| Specification name | Specification value |

|---|---|

| Wire length, processing on both sides min. | 1 mm |

| Wire length max. | 800000 mm |

| Strip lengths, full stripping side 1 max. | 290 mm |

| Strip lengths, full stripping side 2 max. | 150 mm |

| Strip lengths, partial stripping/multiple stripping max. | 999.9 mm |

| Wire outer diameter max. | 35 mm |