Cut and Strip

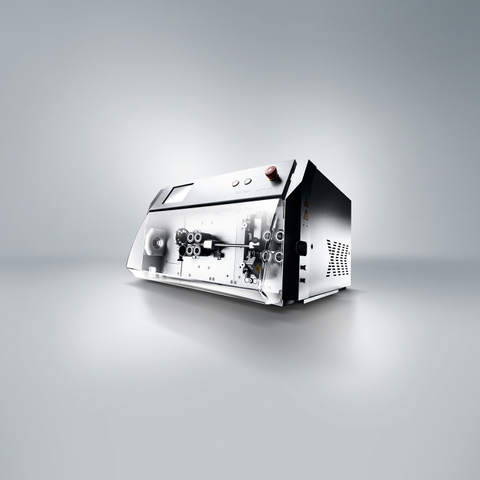

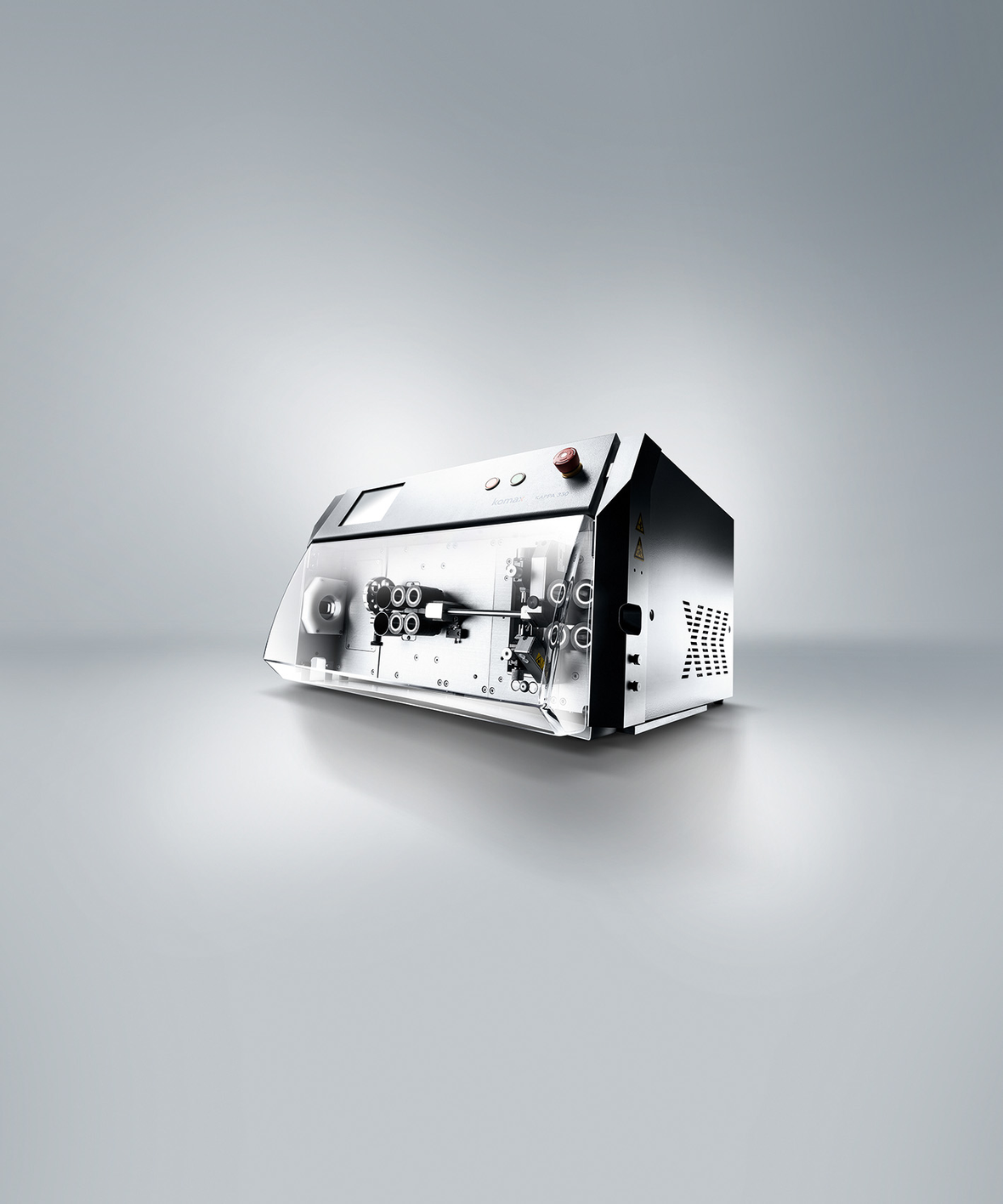

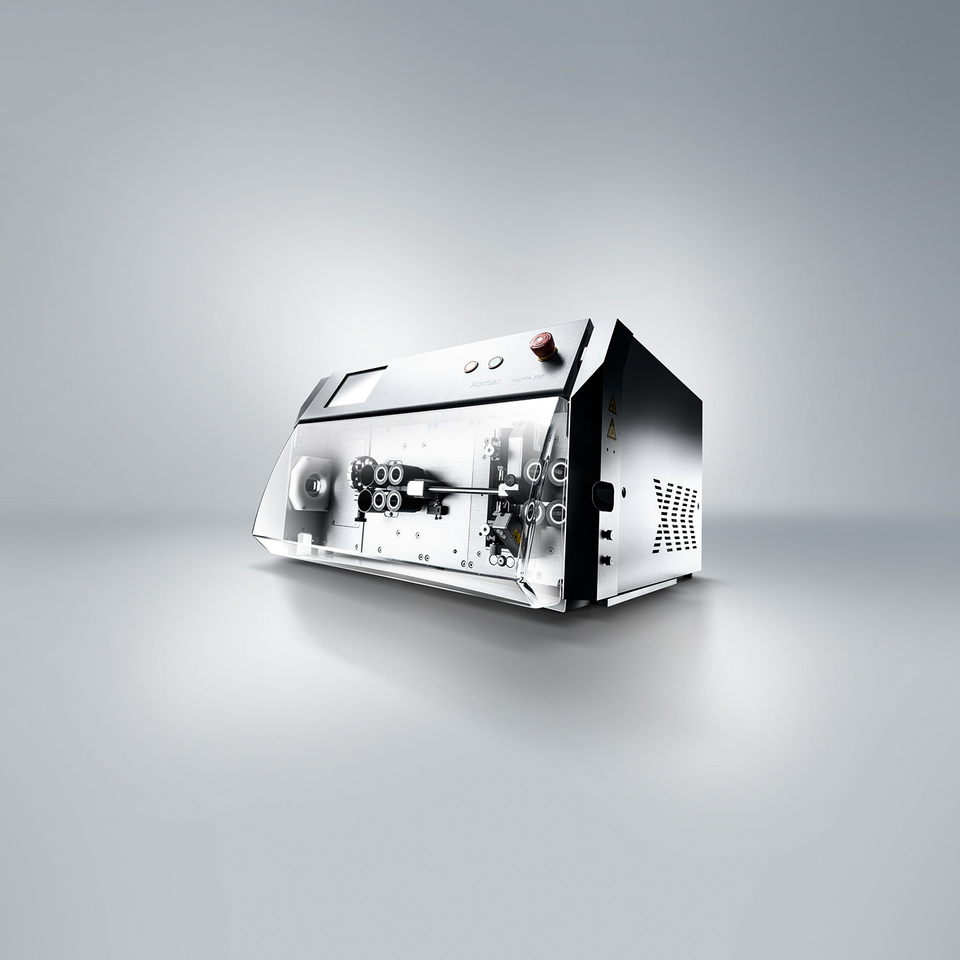

Kappa 330 SH

The Kappa 330 cutting and stripping machine is suitable for processing a wide range of wires as a single head and optionally as a dual head with a double blade cutting head.

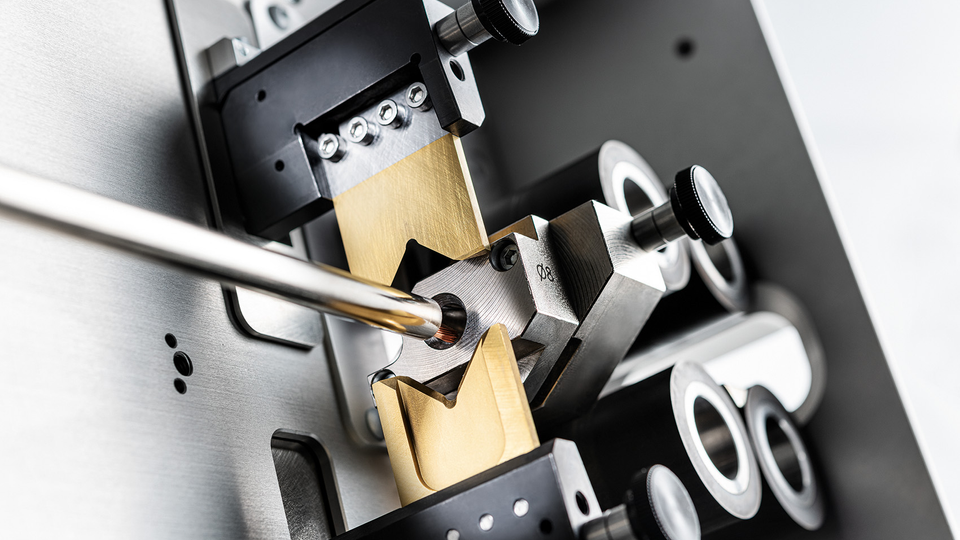

Single head cutting unit with innovative sensor technology

The single head cutting unit covers a wide range of processing areas. The integrated sensors serve as a set-up aid and for process monitoring.

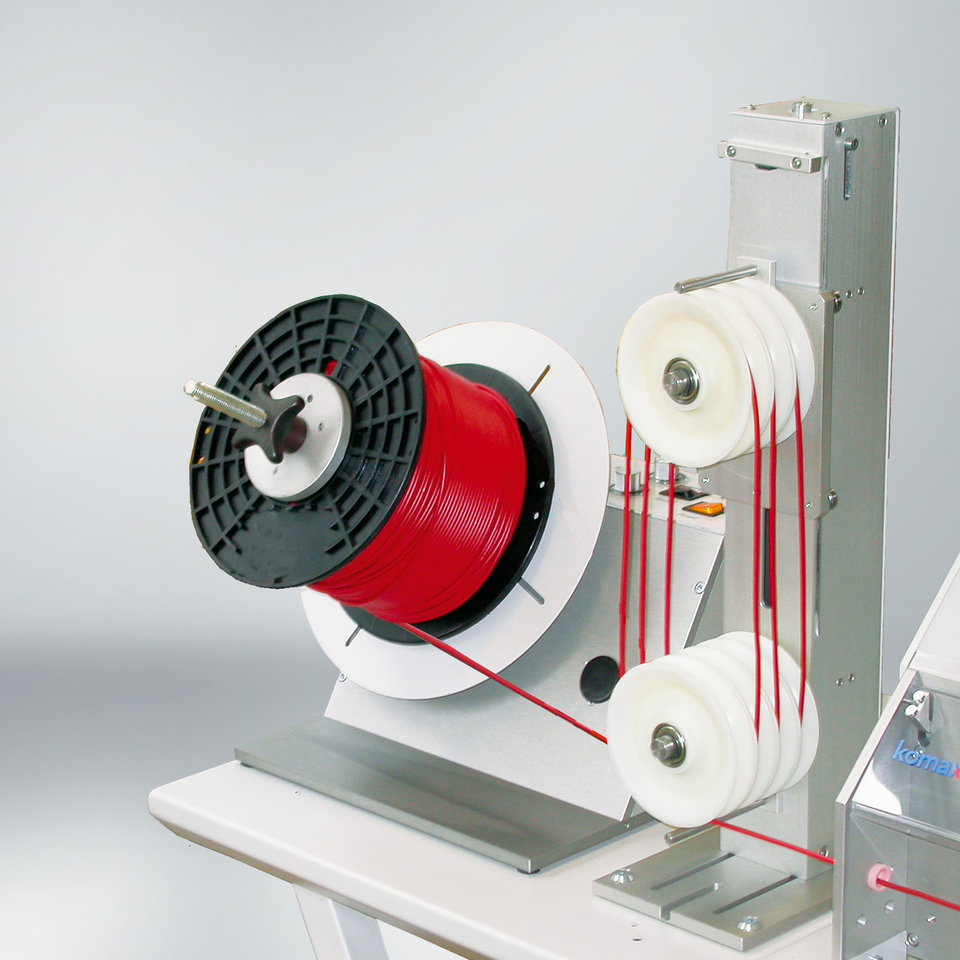

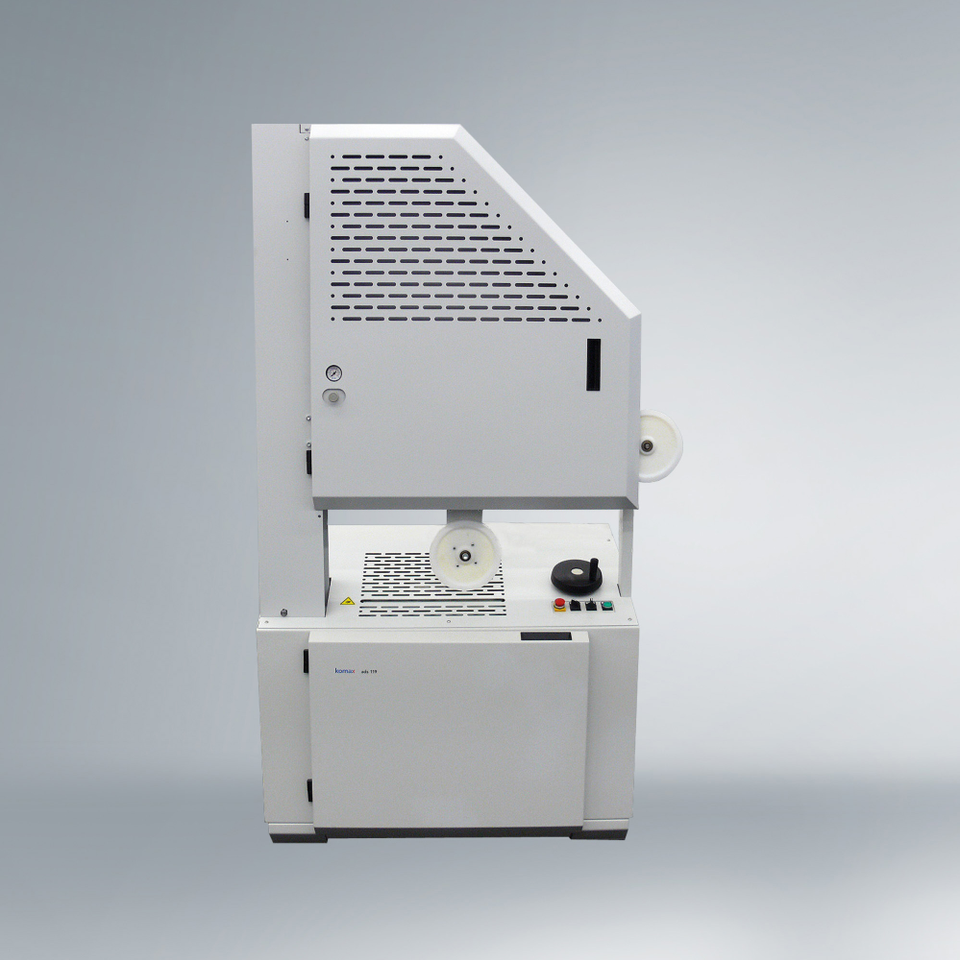

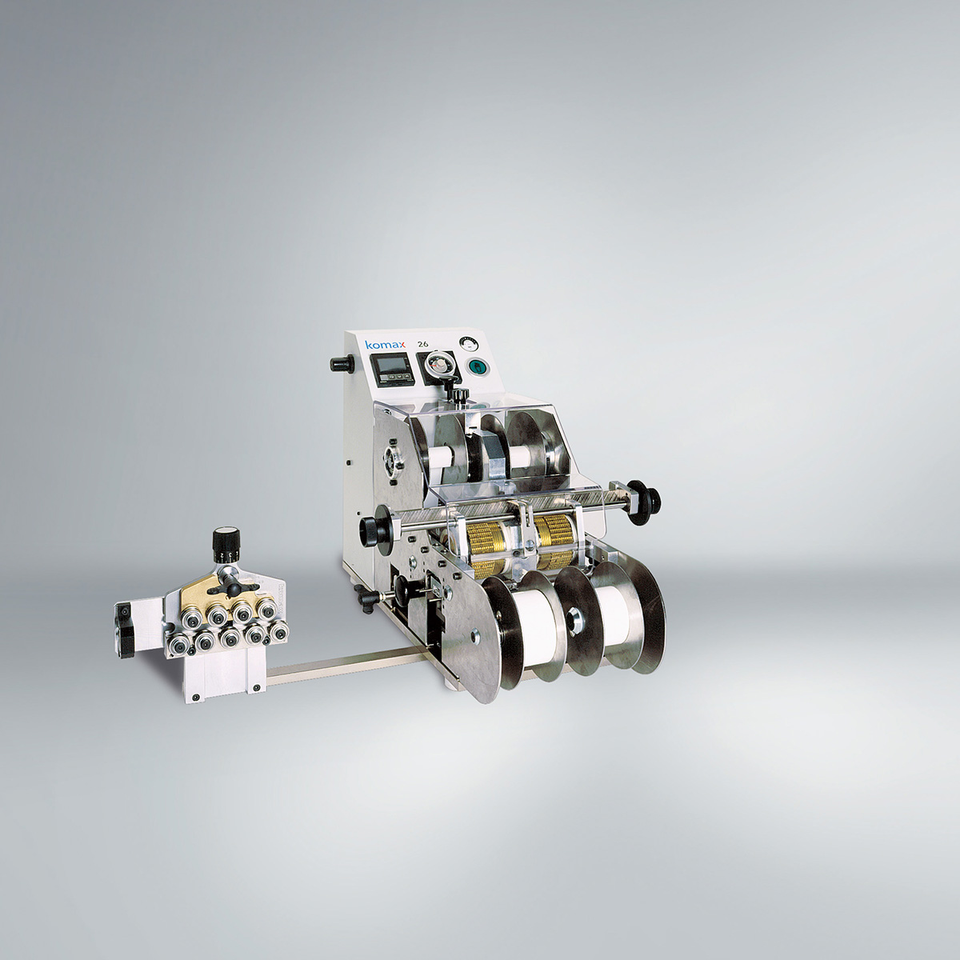

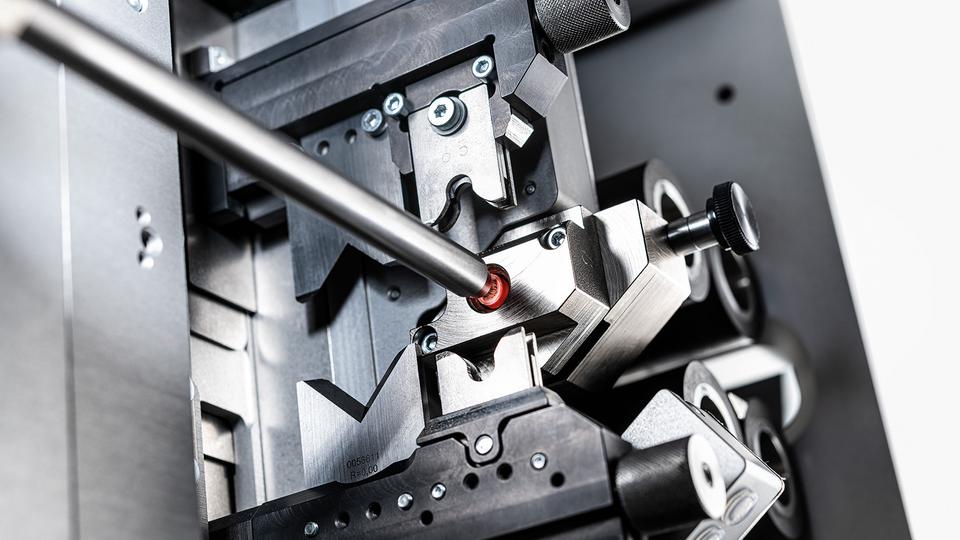

Optional dual head for up to three process steps in one

Dual head with additional separation unit optional

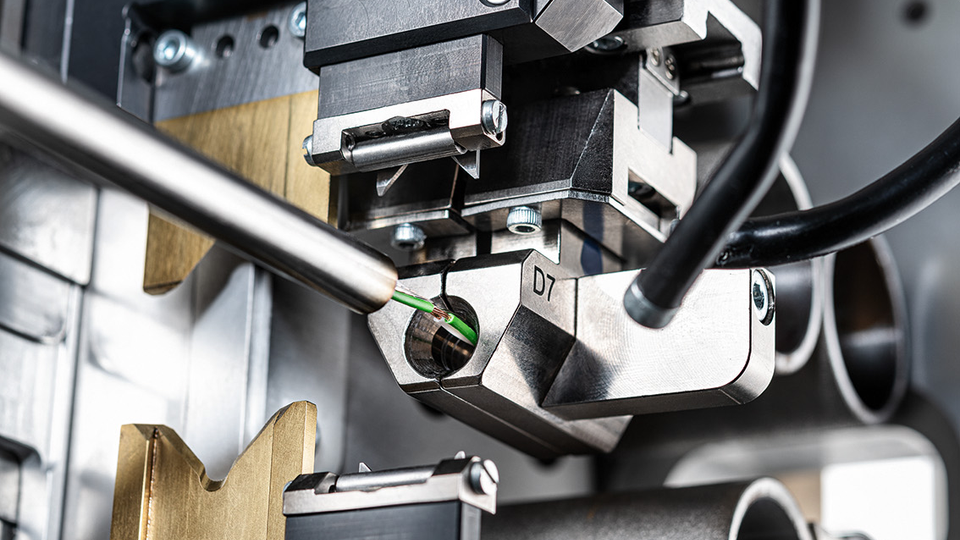

The conductors of the patented roller system are gently pushed apart. This means that several conductors (including twisted conductors) can be separated quickly and gently.

| Specification name | Specification value |

|---|---|

| Wire length, processing on both sides min. | 1 mm |

| Wire length max. | 800000 mm |

| Strip lengths, full stripping side 1 max. | 180 mm |

| Strip lengths, full stripping side 2 max. | 50 mm |

| Strip lengths, partial stripping/multiple stripping max. | 999.9 mm |

| Wire outer diameter max. | 16 mm |