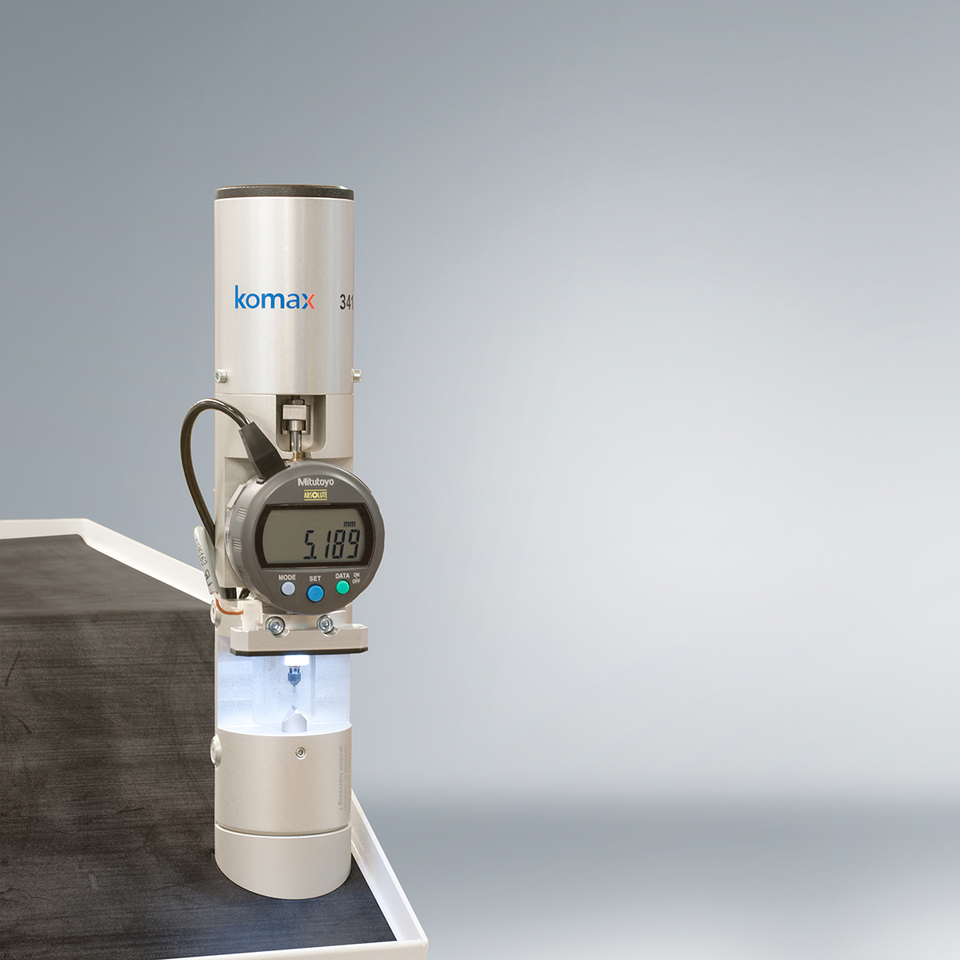

Crimper

Delta 220

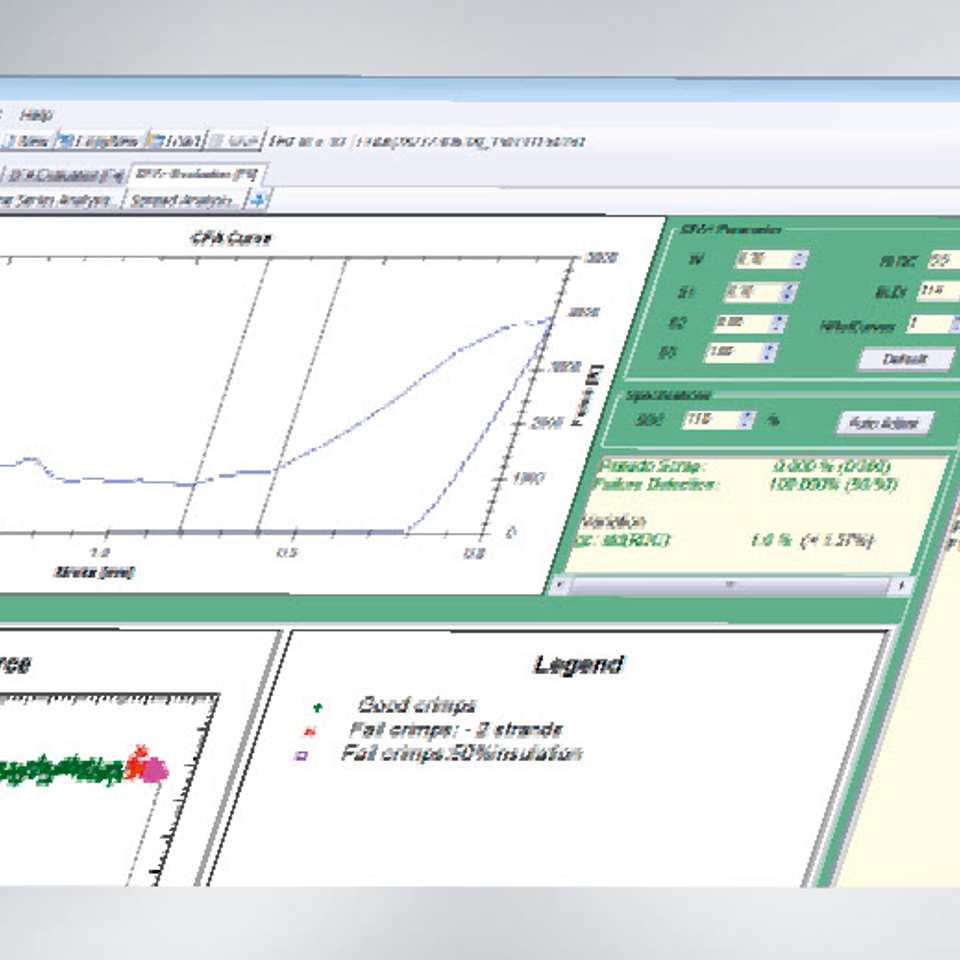

The basic Delta 220 model is a programmable crimping machine with crimp force monitoring and manual crimp height adjustment – optionally with stripping unit and bad contact cutter.

| Specification name | Specification value |

|---|---|

| Strip length min. | 0.1 mm |

| Strip length max. | 13 mm |

| Dismantling length min. | 33 mm |

| Dismantling length with "short dismantling length" option min. | 23 mm |

| Wire cross section, crimping min. | 0.03 mm² |

| Wire cross section, crimping max. | 6.6 mm² |