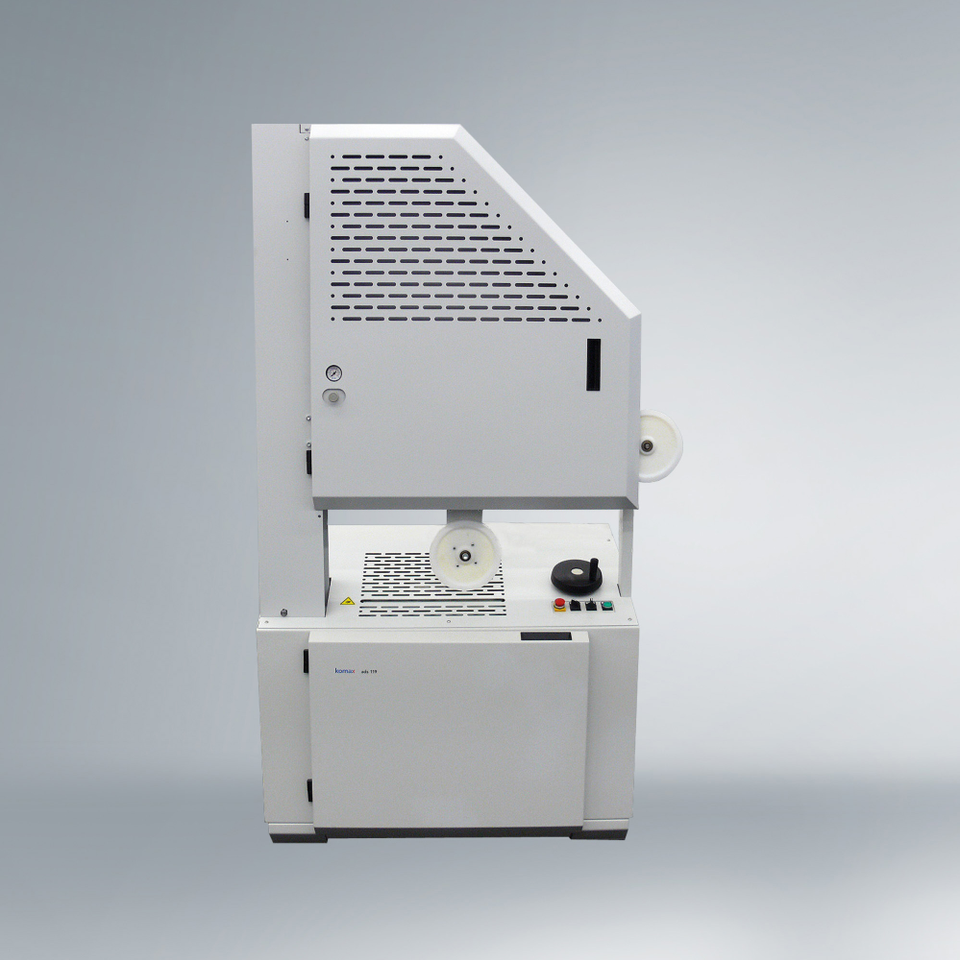

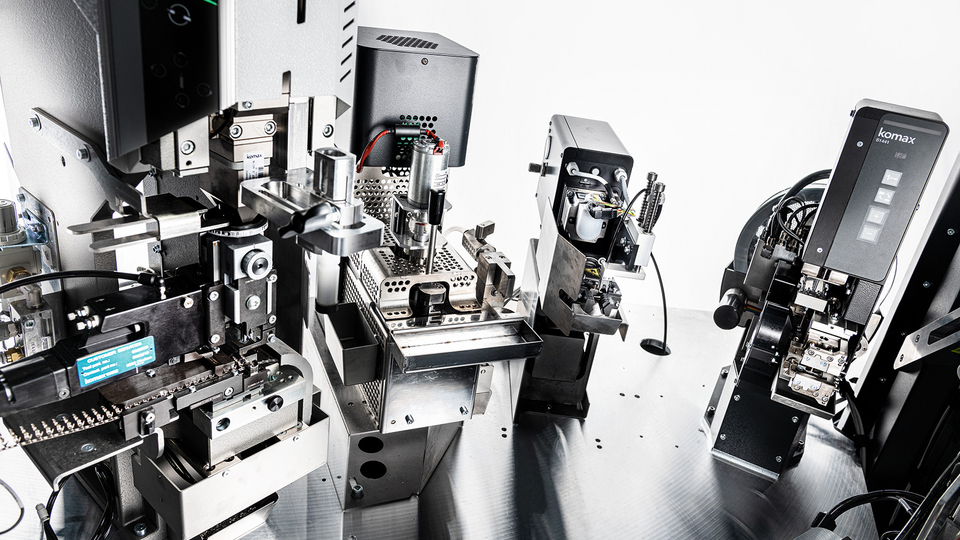

Alpha 565

The Alpha 565 wire processing machine is suitable for special processing with up to seven process stations and conductor cross-section 0.13 – 6 mm²

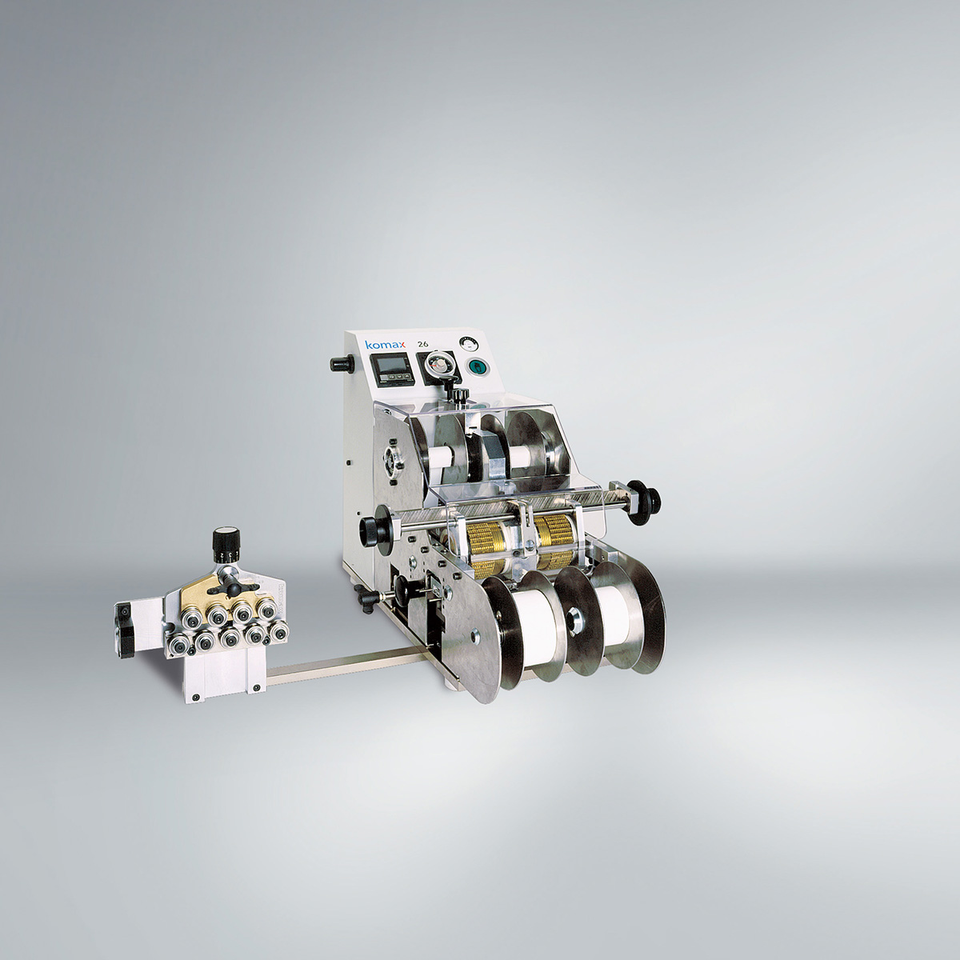

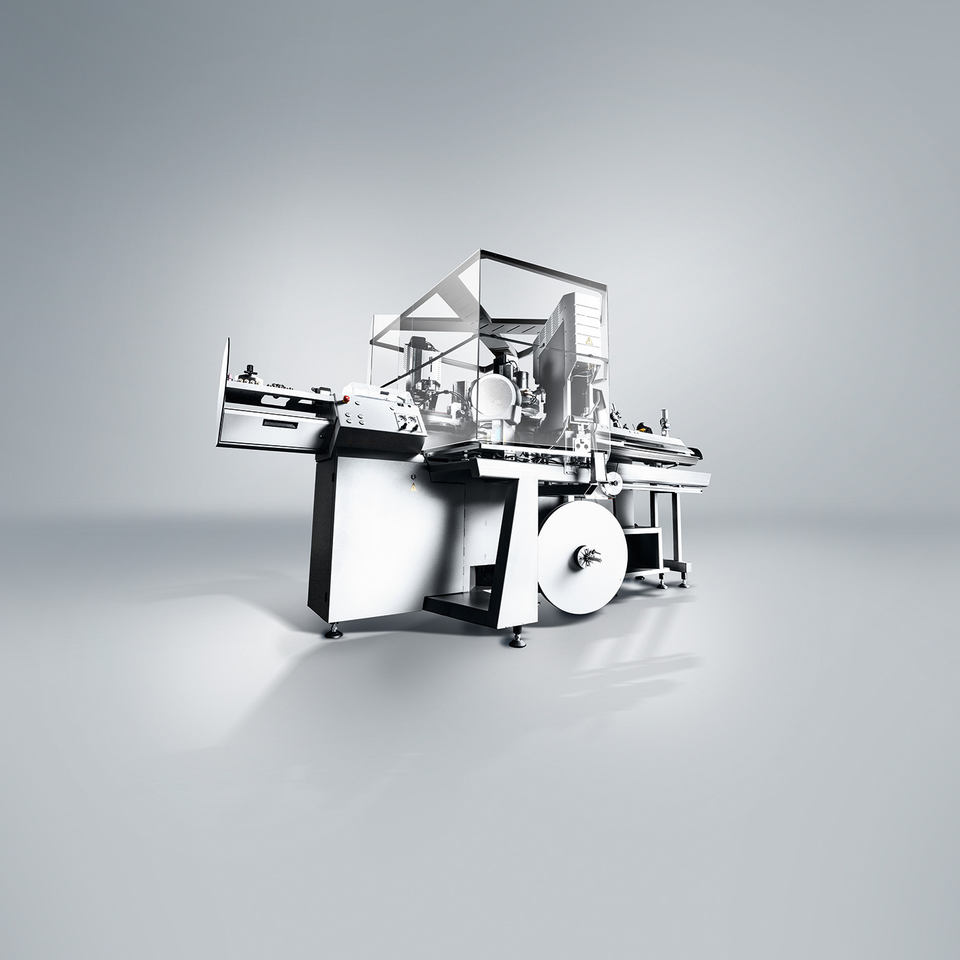

Variety of process combinations due to additional applications

Various crimp, seal, twisting and tinning modules, sleeve loaders or ferrule modules as well as a welding module are possible with the Alpha 565– individual solutions are possible.

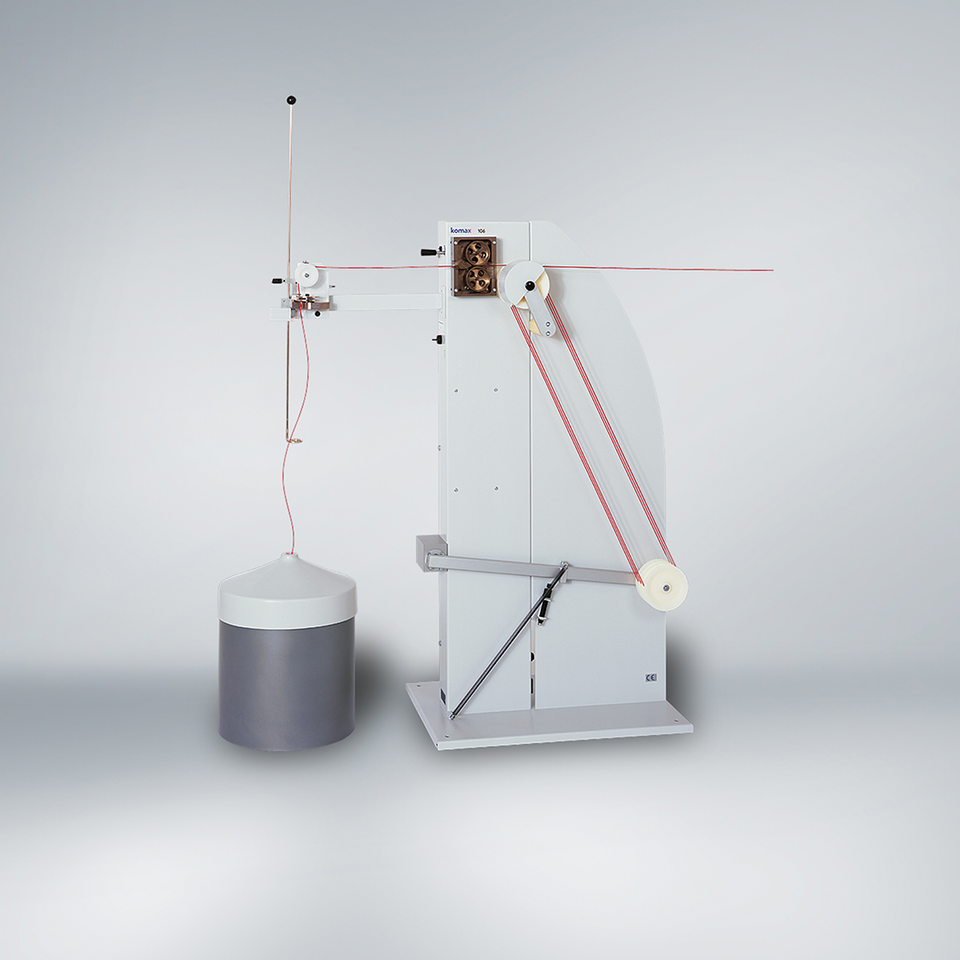

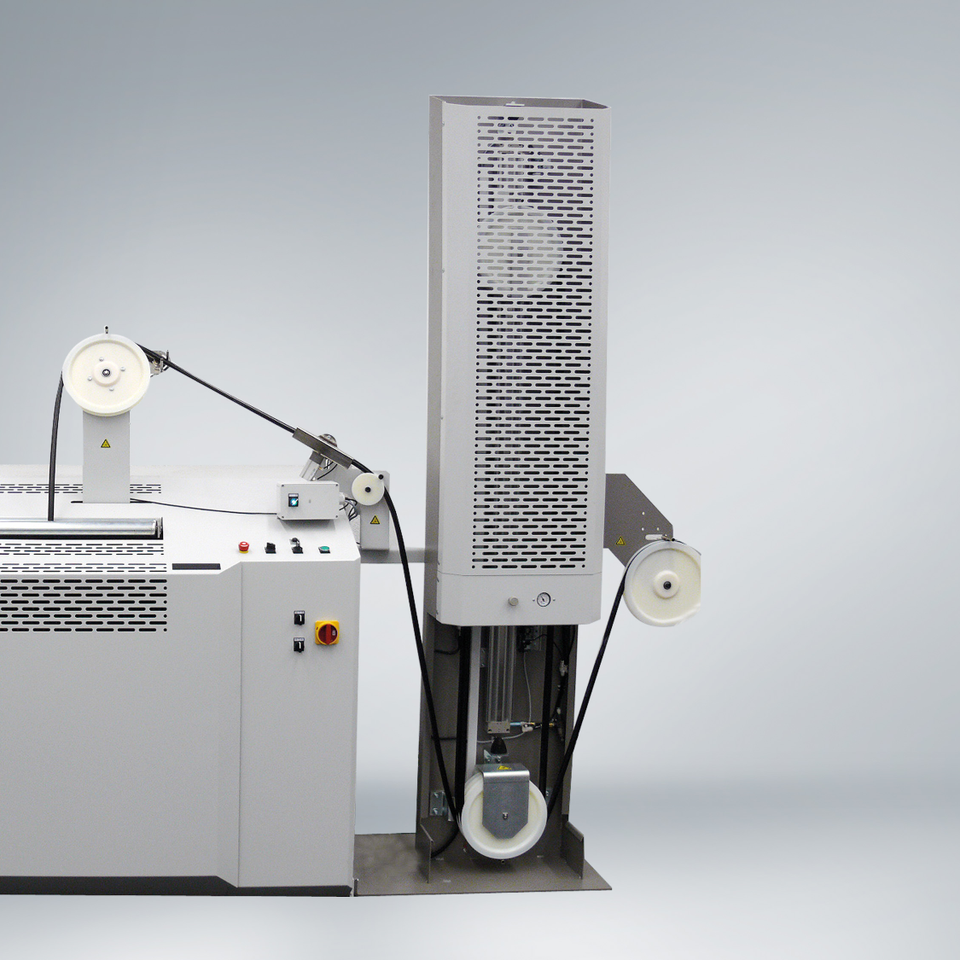

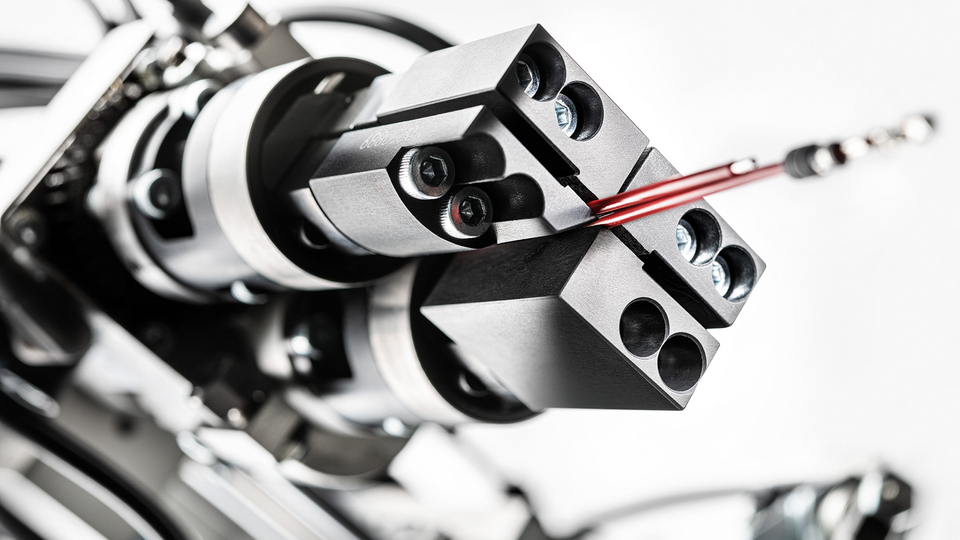

No damage to strands on the twisting unit, even with thin wires

The optional X1582 twisting unit twists quickly and flawlessly stripped wire ends– without damaging strands– even on the thinnest wires.

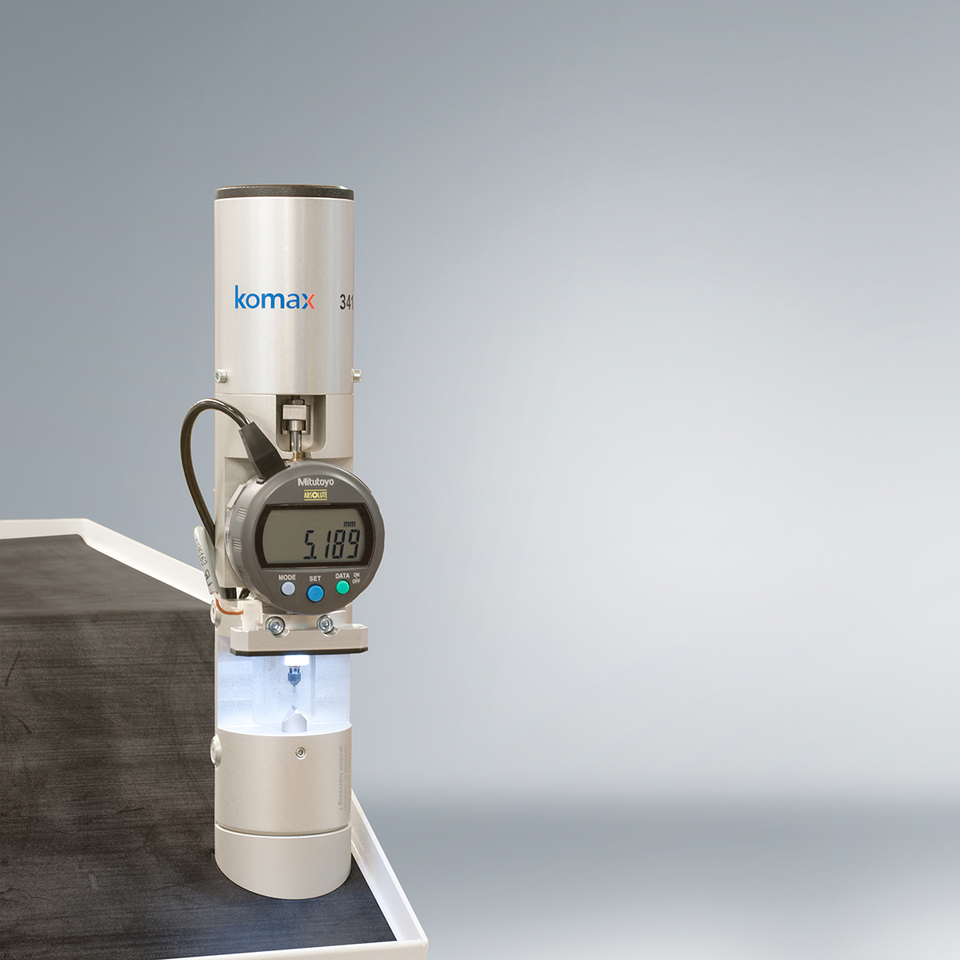

High-quality tin plating thanks to constant flow of tin

The X1585 flux/tinning module for Komax fully-automatic machines enables versatile, lead-free tinning of stranded ends. Constant flow of tin ensures consistent quality.

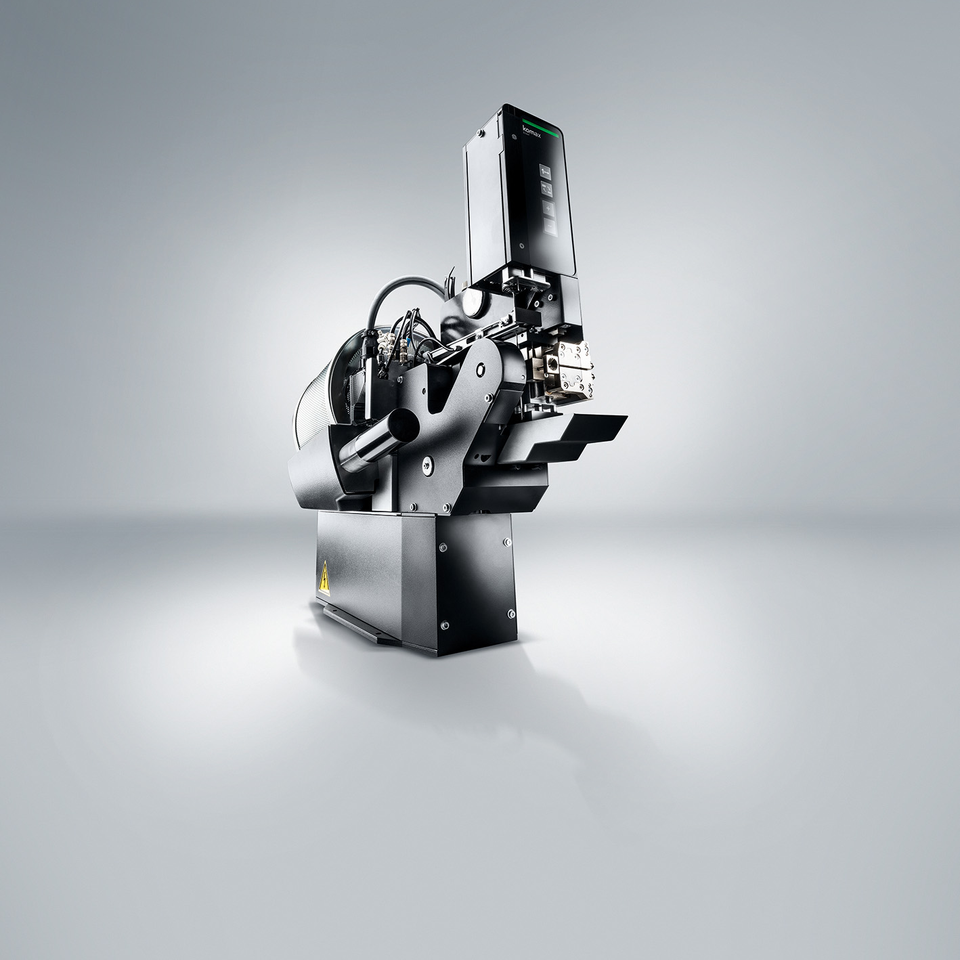

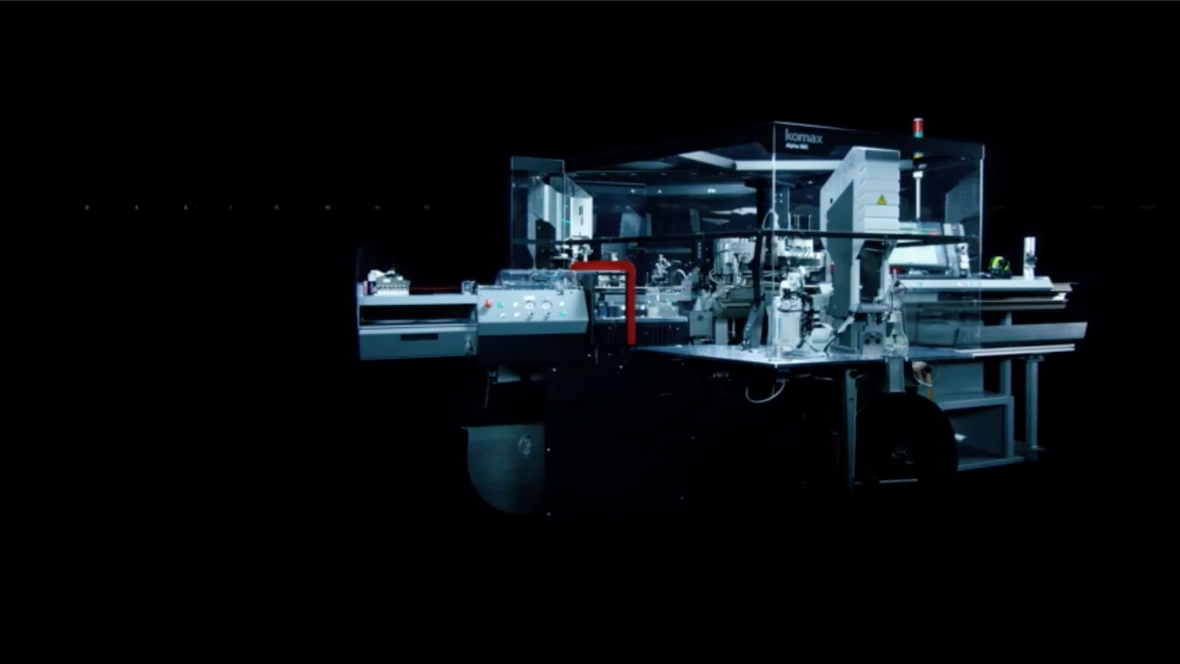

Optional double gripper module for processing two wires

Two wires are brought together with the ingenious rotary gripper. The wire gripper then takes over the two wires and swivels them on to the crimp module.

| Specification name | Specification value |

|---|---|

| Wire cross section min. | 0.13 mm² |

| Wire cross section max. | 6.0 mm² |

| Wire length, single-sided processing min. | 60 mm |

| Wire length, processing on both sides min. | 60 mm |

| Wire length, processing on both sides (optional from) min. | 30 mm |

| Wire length max. | 12000 mm |