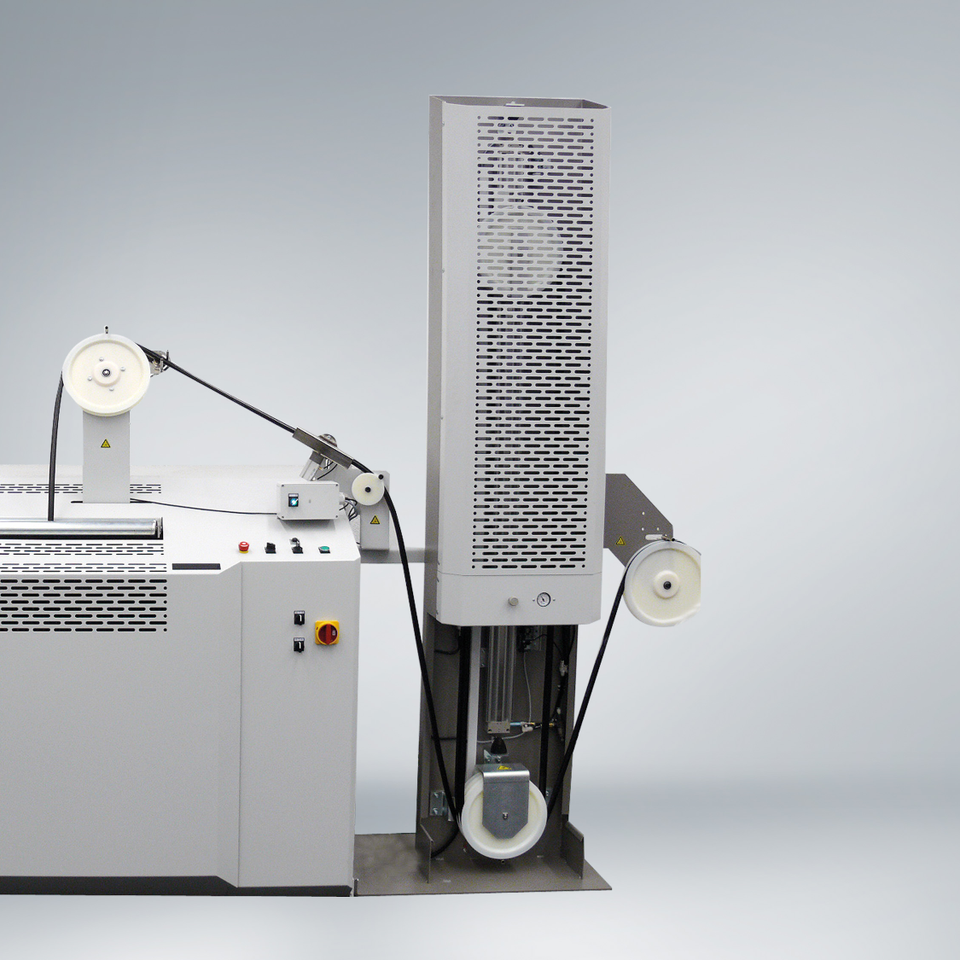

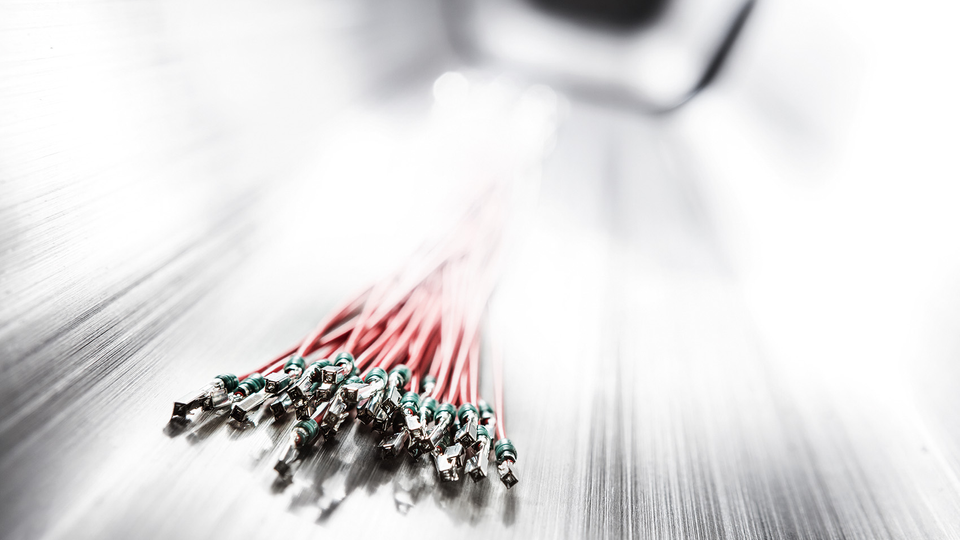

Crimp to Crimp

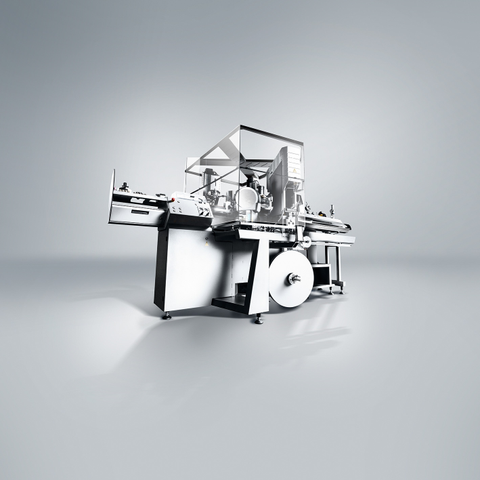

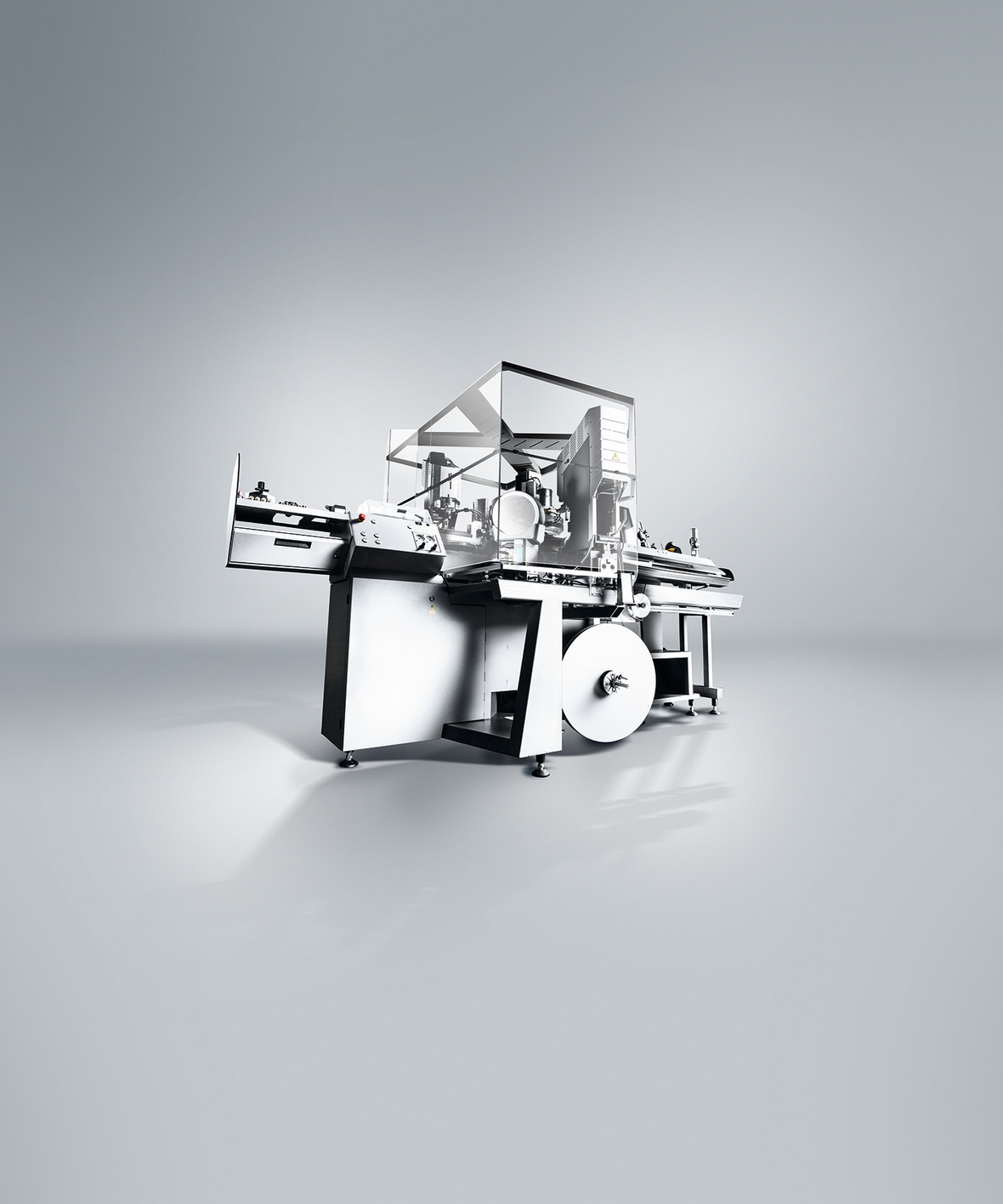

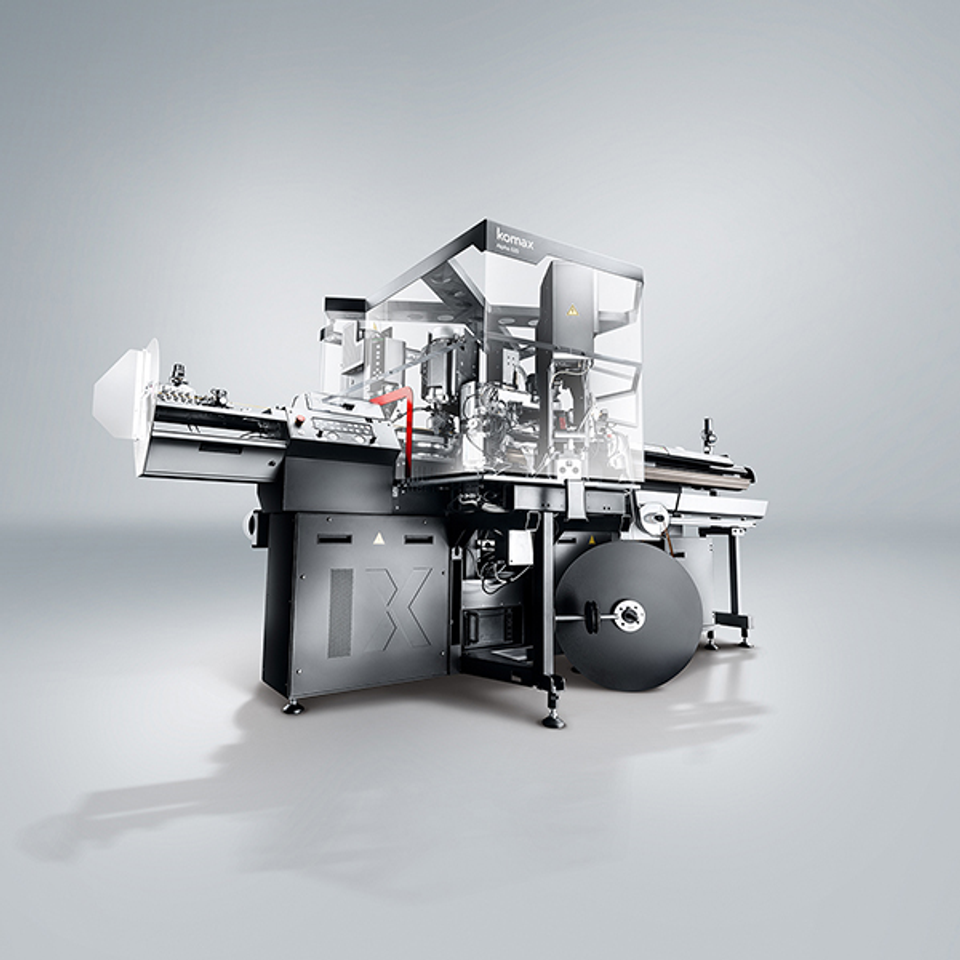

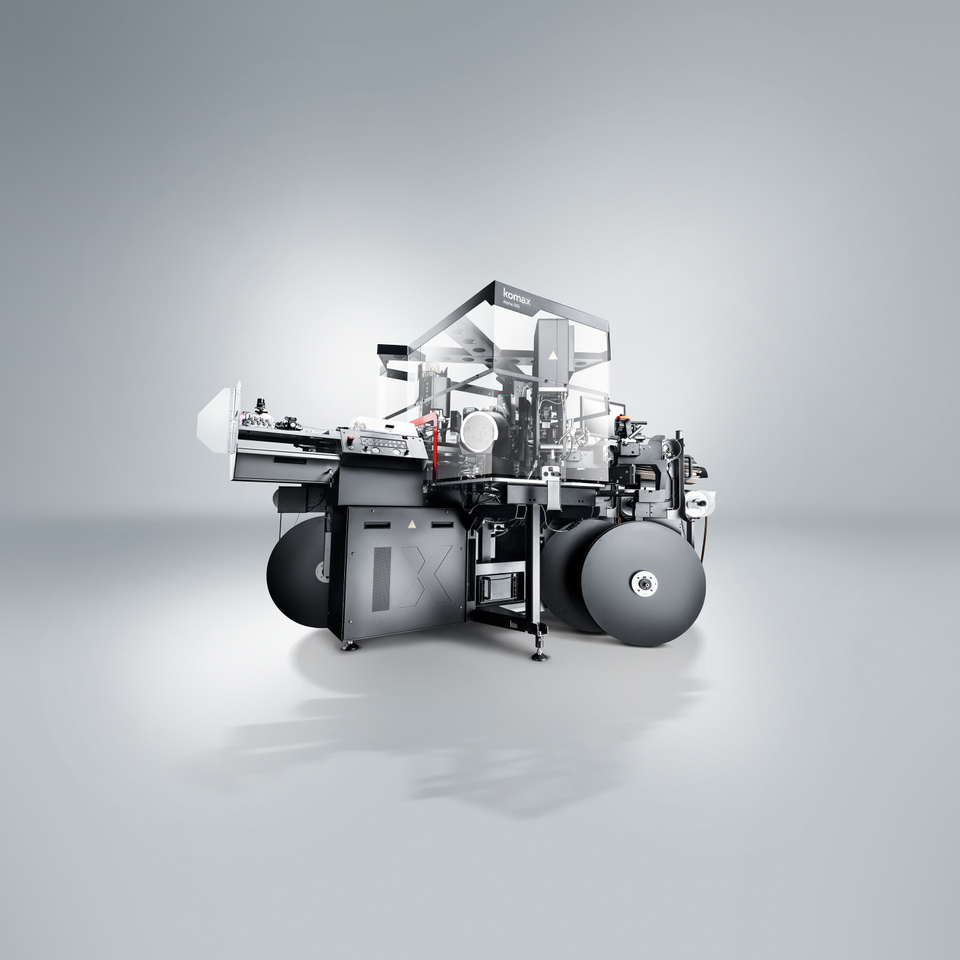

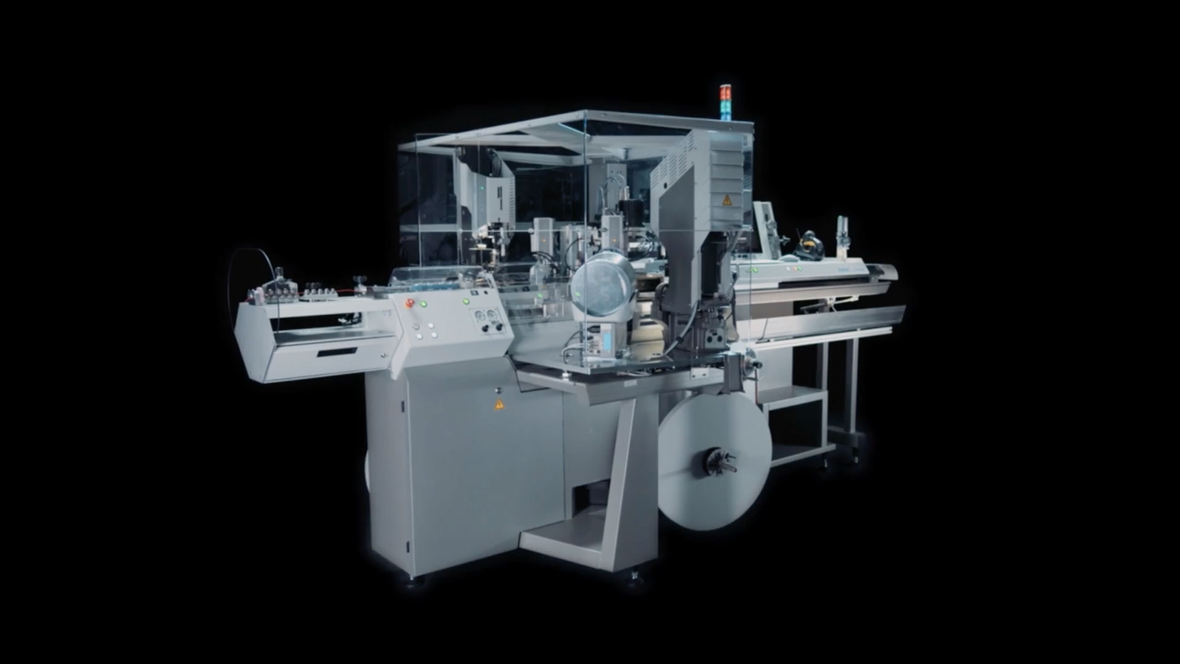

Alpha 530

The fully automatic Alpha 530 wire processing machine for crimping and seal insertion on both sides meets high quality requirements for wire cross-sections of 0.13 – 6 mm².

Quick change of guide tubes possible without tools

Easy-to-reach tools in a practical drawer under the wire draw-in

Smooth steel tray for safe storage of finished wires

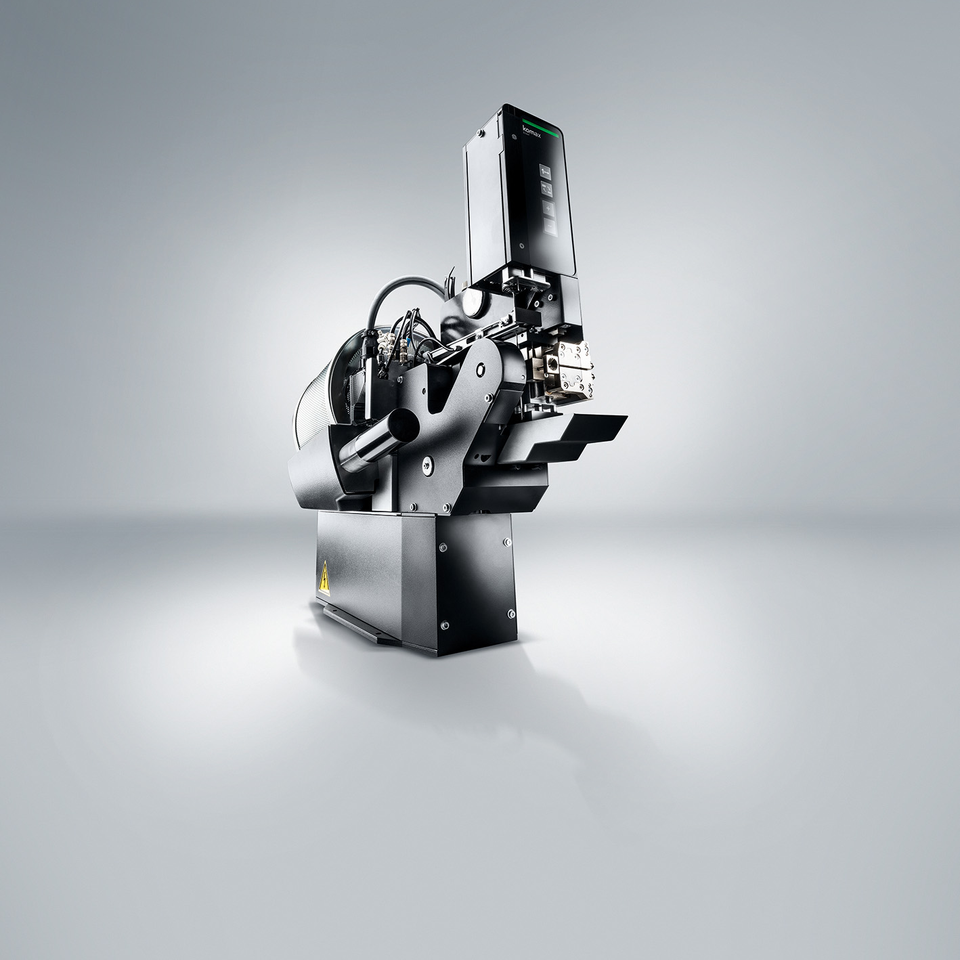

Efficient setup directly on the crimp module

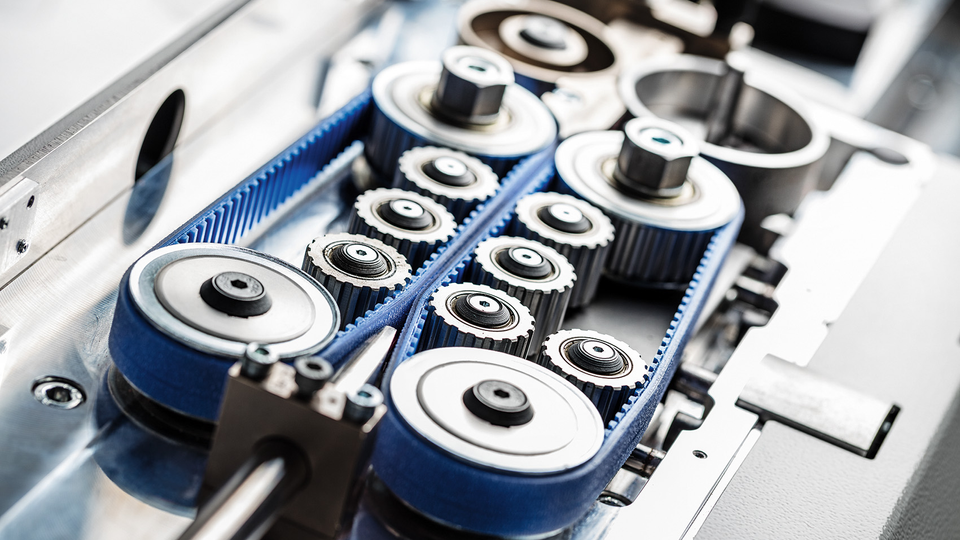

Reliable and fast belt drive with 9m/s draw-in

| Specification name | Specification value |

|---|---|

| Wire cross section min. | 0.13 mm² |

| Wire cross section max. | 6.0 mm² |

| Wire length, single-sided processing min. | 60 mm |

| Wire length, processing on both sides min. | 60 mm |

| Wire length, processing on both sides (optional from) min. | 30 mm |

| Wire length max. | 65000 mm |