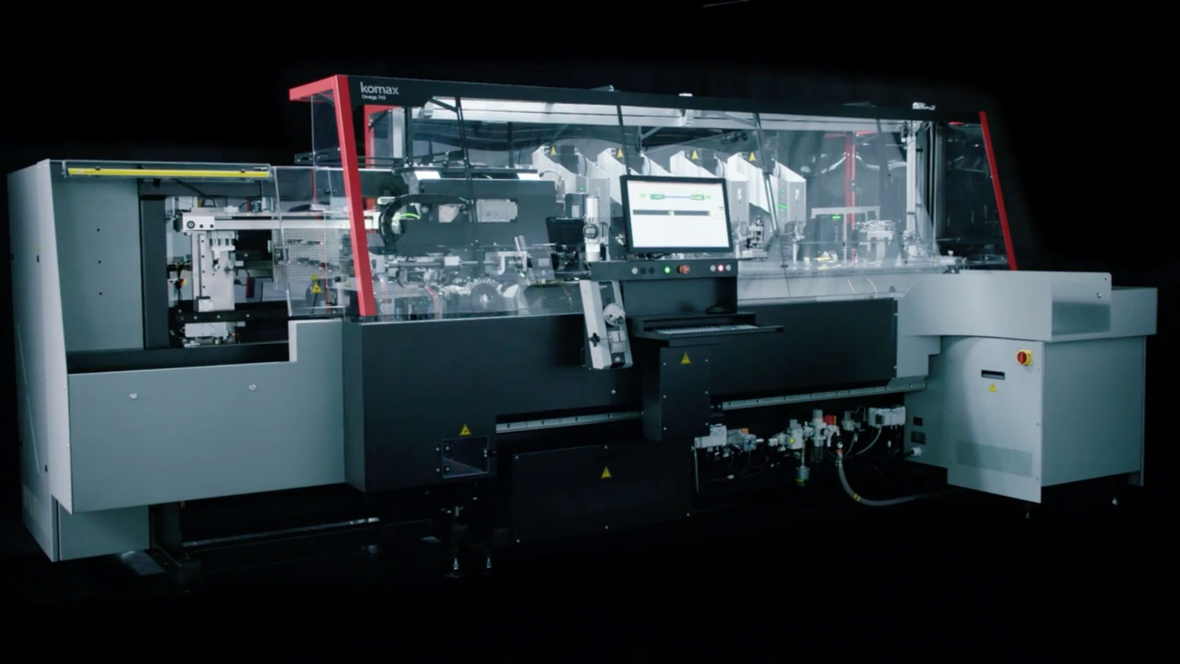

Omega 740

A máquina de montagem de cabos Omega 740/750 pode ser usada para produzir chicotes elétricos de várias complexidades e equipá-los com inserção em conectoresl em um ou ambos os lados.

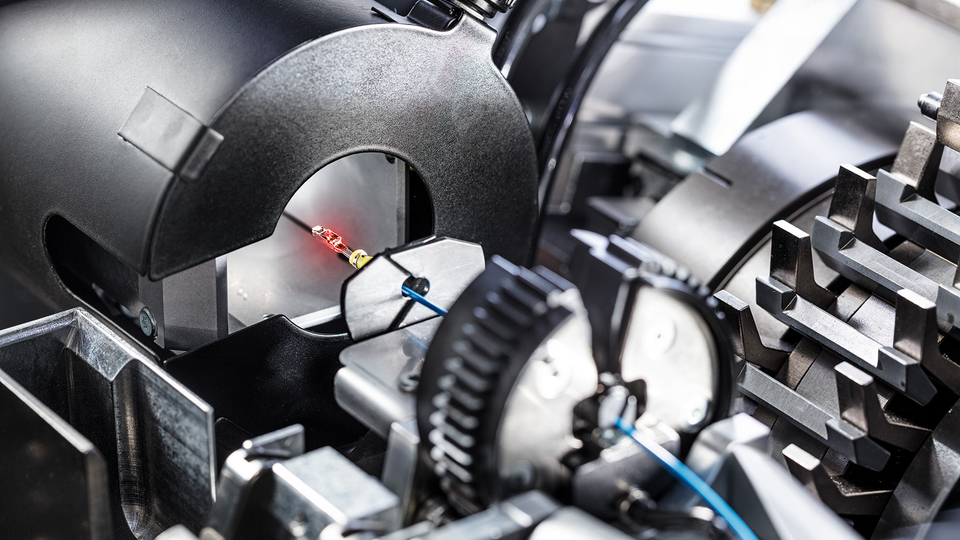

Sistema de medição de terminal óptico para inserção de vários terminais

O sistema de medição de terminal óptico permite a inserção de uma ampla variedade de terminais em conectores de terminal, tanto em um lado quanto em ambos.

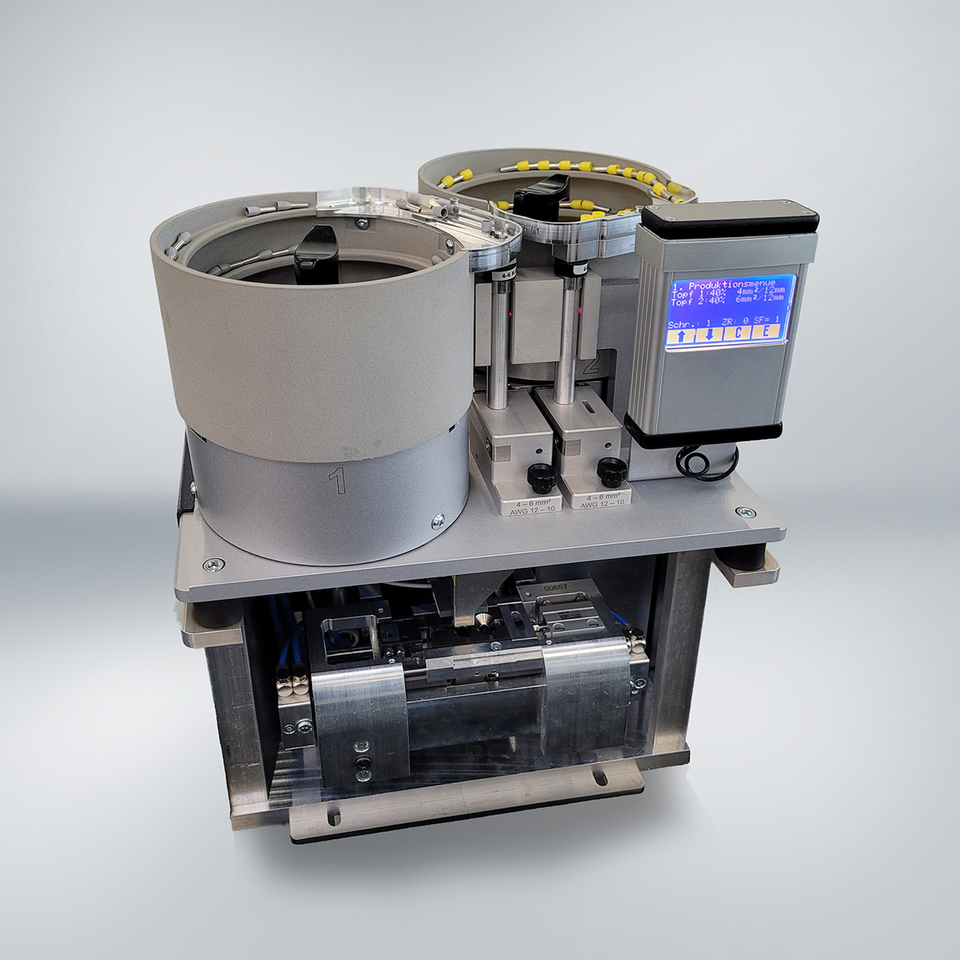

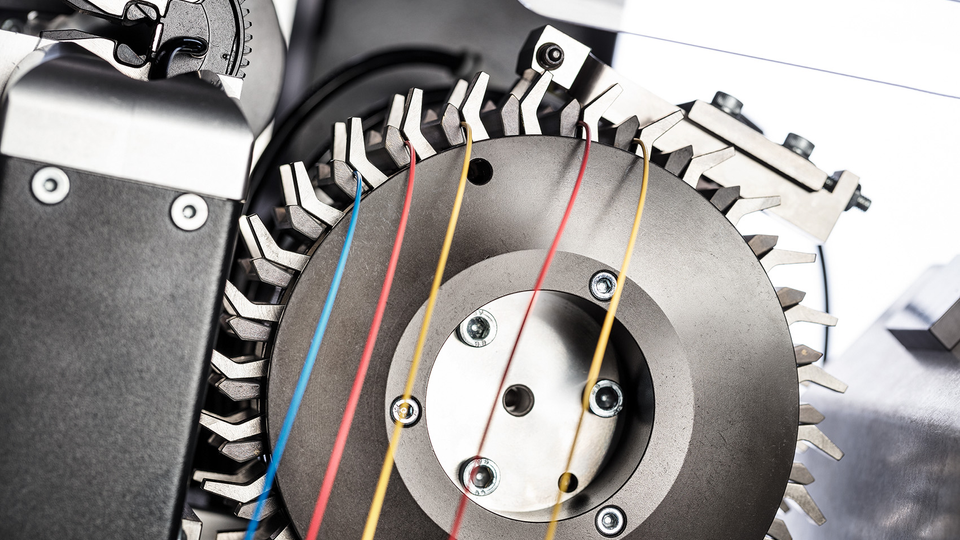

Amplo trocador para até 36 cabos diferentes

O trocador de cabos automático fornece até 36 cabos de diferentes bitolas. Isso abrange, por exemplo, a ampla variedade de projetos de gabinetes de controle.

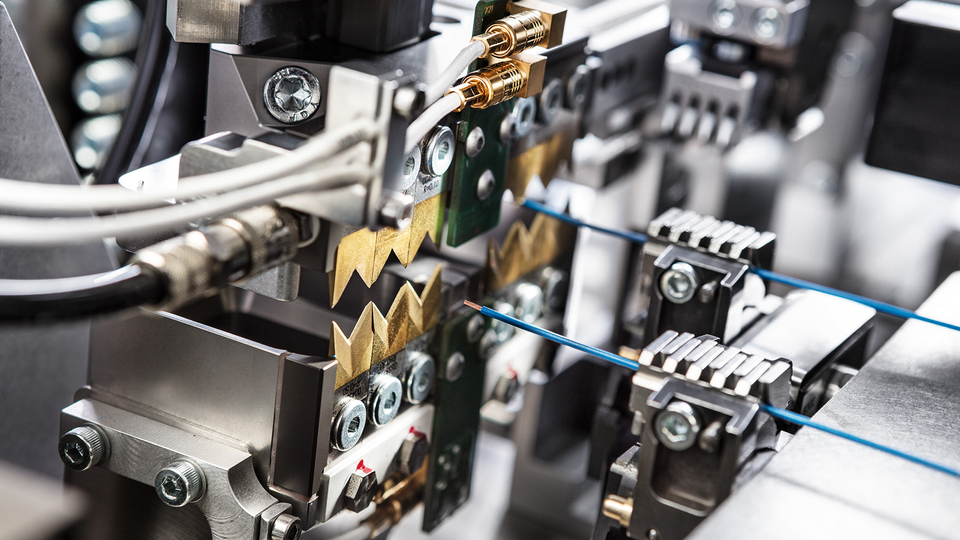

Três pares de facas com monitoramento da incisão (ACD) opcional

Os três pares de facas já integrados com o opcional de monitoramento da incisão (ACD) abrangem uma faixa de secção transversal de 0,13 a 2,5 mm² (AWG 26–14).

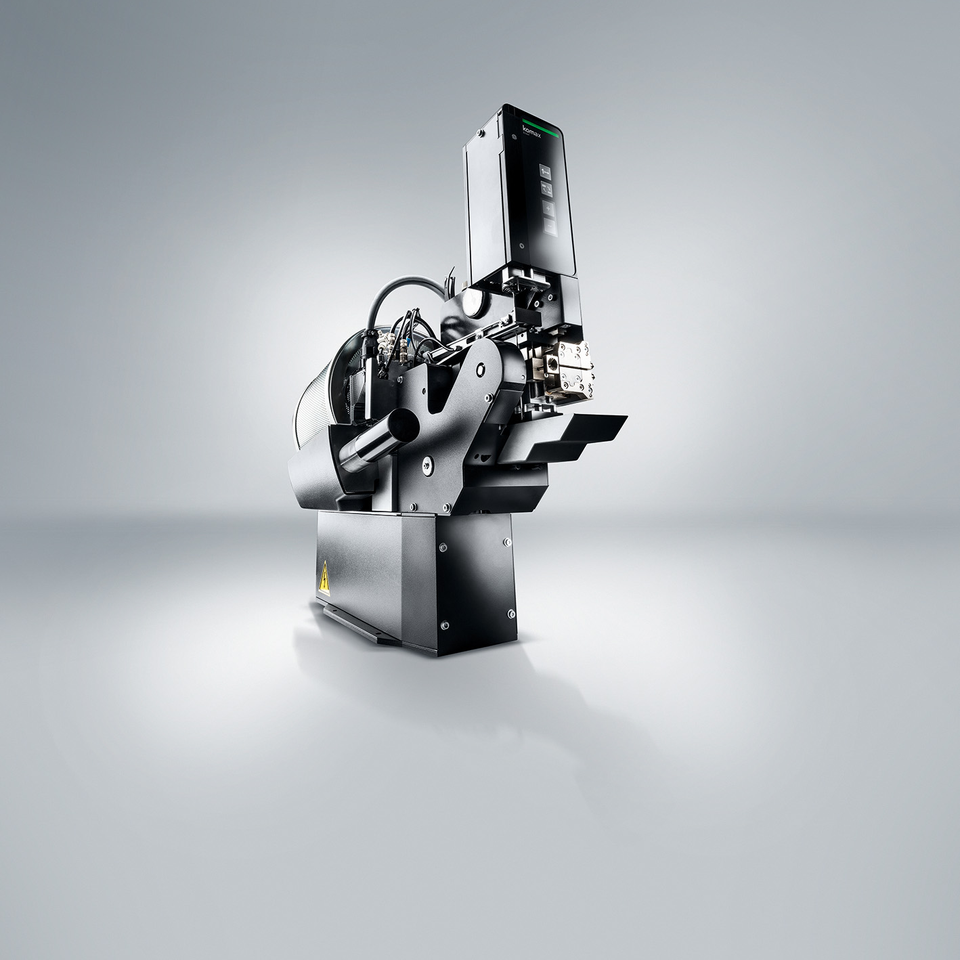

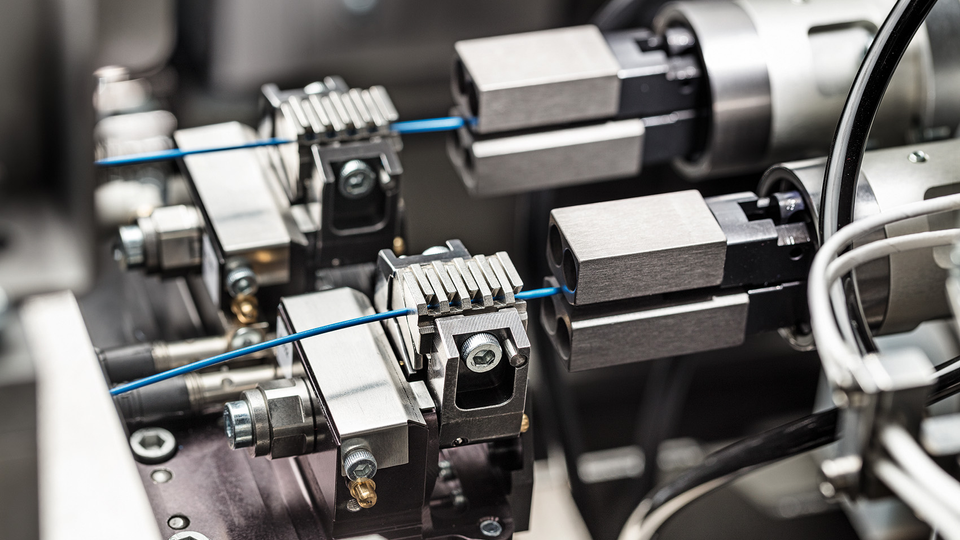

Módulo especial de destorção para neutralizar cabos torcidos

Cabos desbobinados sempre têm uma torção. O módulo de destorção remove a torção dos cabos, o que é importante à inserção totalmente automática subsequente.

Armazenamento de cabos integrado para uma produção mais eficiente

Com a ajuda do sistema de armazenamento de cabos, é possível produzir com facilidade chicotes elétricos com conectores nos dois lados e elevado nível de complexidade. Também permite a pós-produção imediata de cabos com defeito.

| Specification name | Specification value |

|---|---|

| Comprimento do cabo mais curto para processamento de um lado | 240 mm |

| Comprimento do cabo mais curto, conexão de jumper dos dois lados | 300 mm |

| Comprimento do cabo mais curto, conexão de jumper dos dois lados máx. | 540 mm |

| Comprimento do cabo mais curto, inserção complexa mín. | 300 mm |

| Comprimento do cabo mais curto, inserção complexa máx. | 760 mm |

| Comprimento do cabo (depósito padrão) máx. | 3000 mm |